Revision History

|

Rev. |

Description of Modification |

Date |

|

1 |

First Issue for Comments |

23/08/2023 |

|

2 |

Second Issue for Comments |

29/08/2023 |

Revision History

|

Rev. |

Description of Modification |

Date |

|

1 |

First Issue for Comments |

23/08/2023 |

|

2 |

Second Issue for Comments |

29/08/2023 |

CONTENTS

6. Summary of Exceedance, Complaints, Notification of Summons and Prosecitions.................... 22

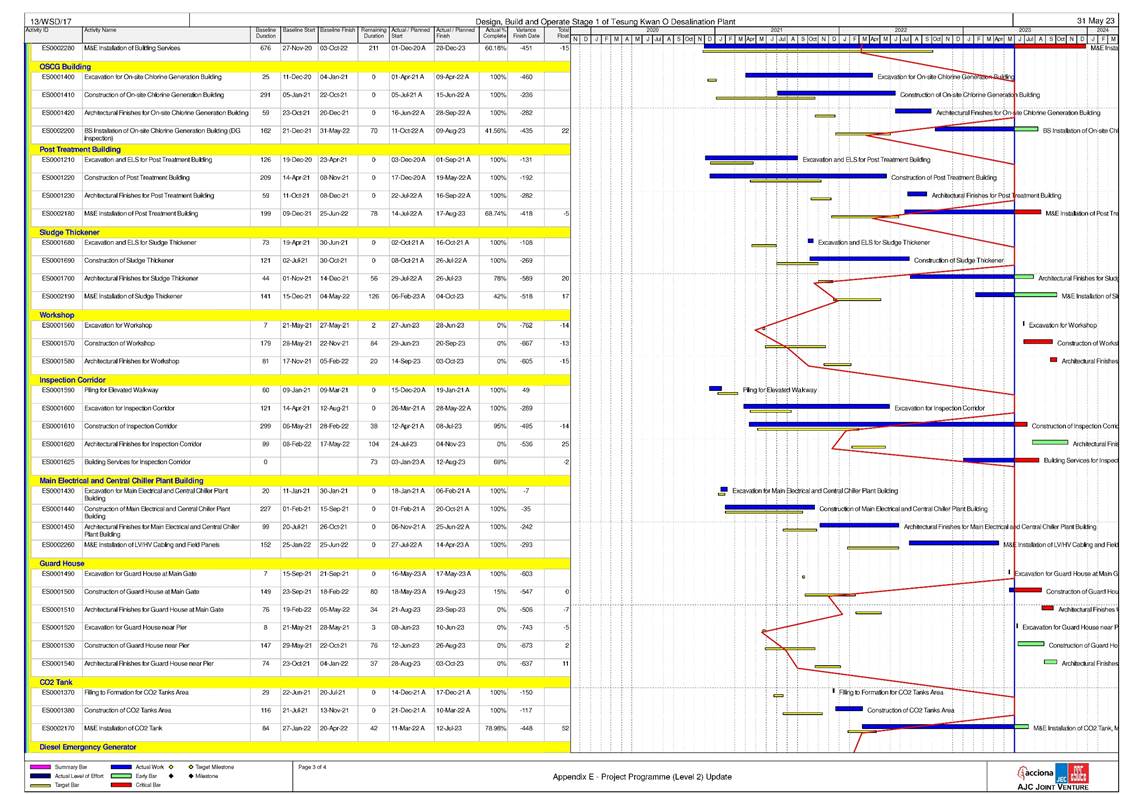

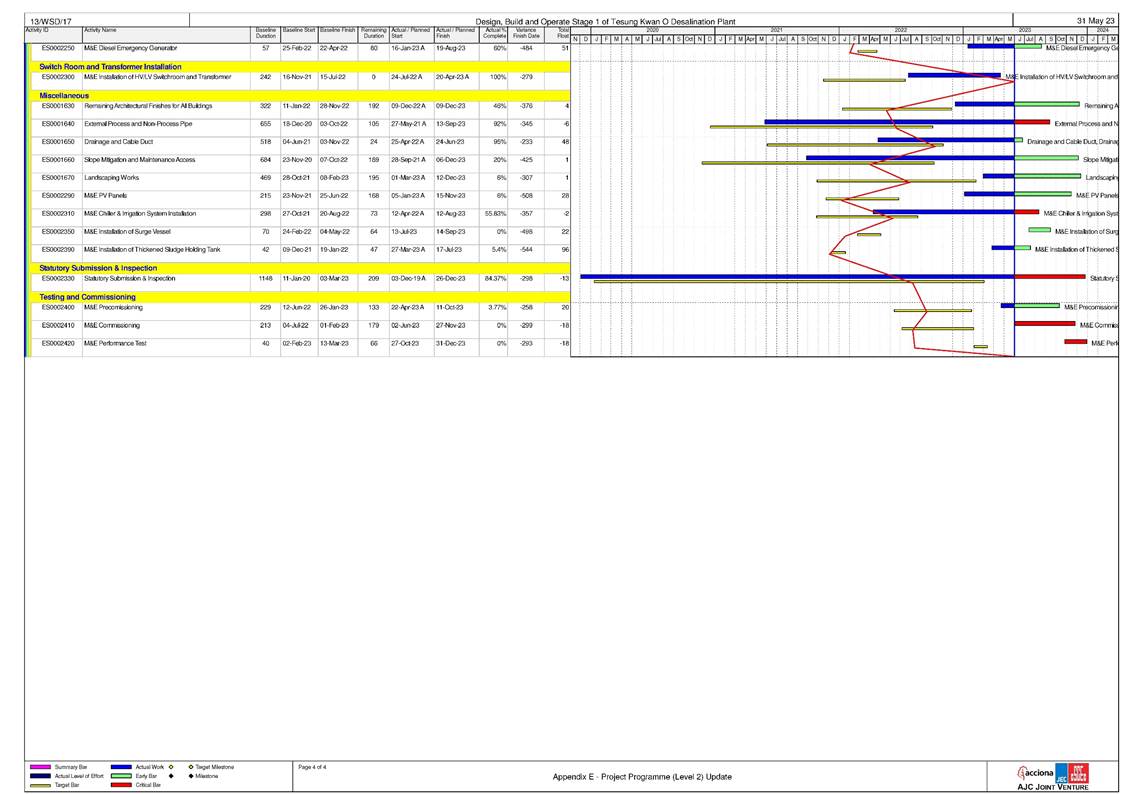

Appendix A Master Programme

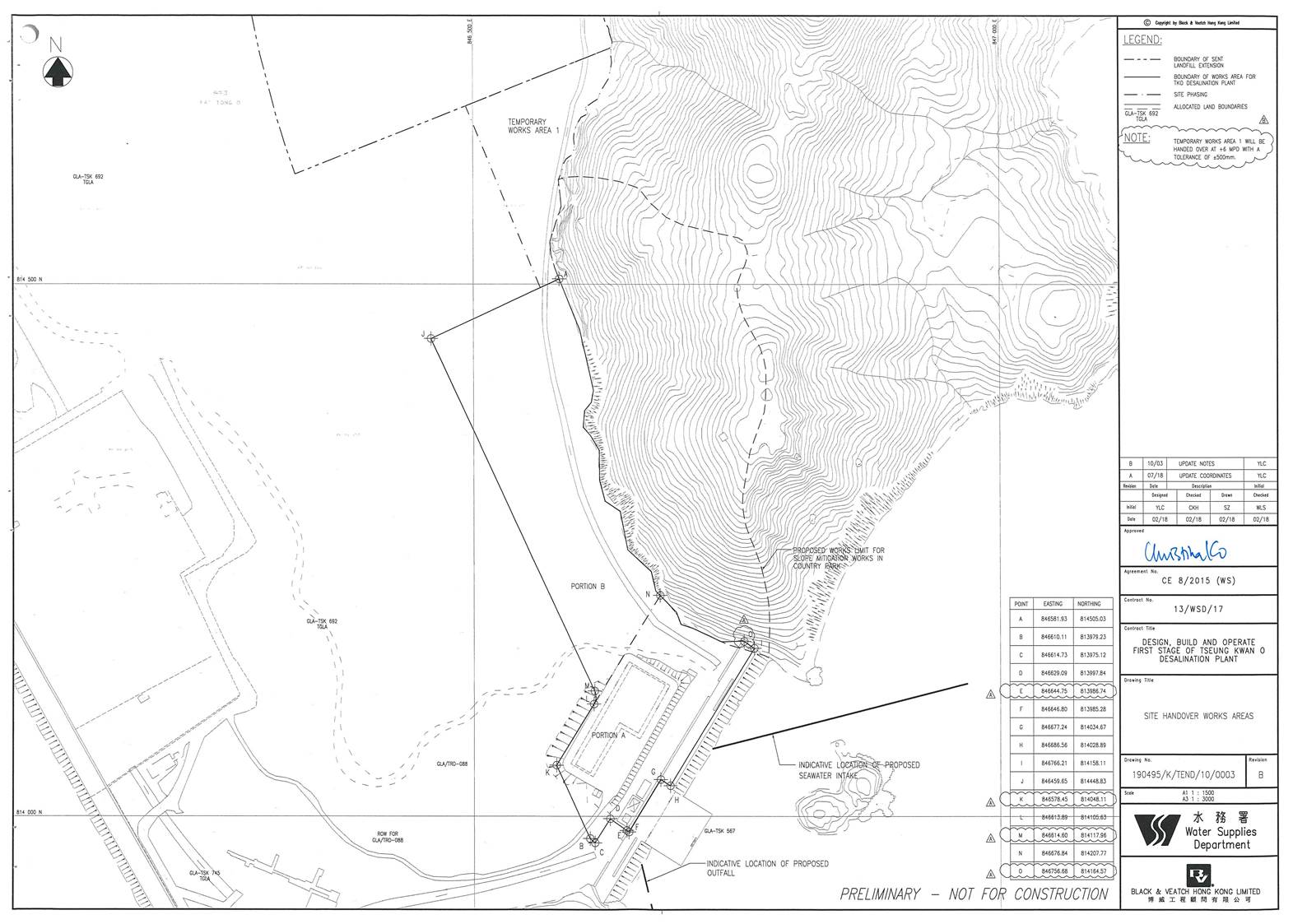

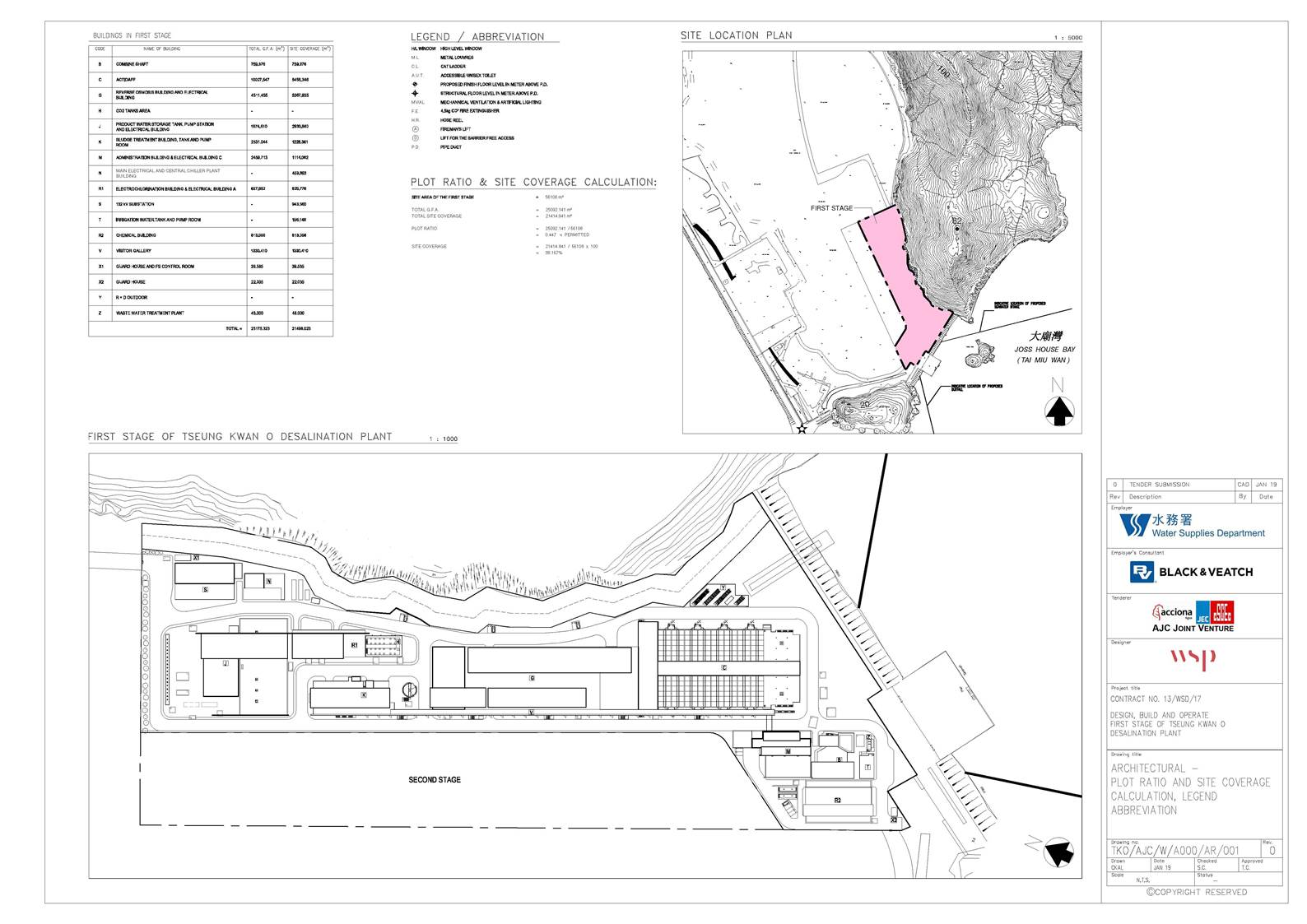

Appendix B Overview of Desalination Plant in Tseung Kwan O

Appendix C Summary of Implementation Status of Environmental Mitigation

Appendix D Water Quality Graphical Presentation

Appendix E Site Inspection Proforma

Appendix F Waste Flow Table

Appendix G Summary of Exceedances

Appendix H Complaint Log

Appendix I Event/Action Plan for Noise and Water Quality Monitoring Exceedance

A1. The Project, Design, Build and Operate First Stage of Tseung Kwan O Desalination Plant (TKODP), is a Designated Project under the Environmental Impact Assessment Ordinance (Cap. 499) (EIAO) and is currently governed by a Further Environmental Permit (EP No. FEP - 01/503/2015/A) for the construction and operation of the Contract.

A2. In accordance with the Environmental Monitoring and Audit (EM&A) Manual for the Contract, EM&A works for marine water quality, noise, waste management and ecology should be carried out by Environmental Team (ET), Acuity Sustainability Consulting Limited (ASCL), during the construction phase of the Contract.

A3. This is the 3rd Annual EM&A Review Report, prepared by ASCL, for the Contract summarizing the monitoring results and audit findings of the EM&A programme at and around Tseung Kwan O Area 137 (TKO 137) during the reporting period from 1 May 2022 to 30 April 2023.

A4. The EM&A programme for this contract has covered environmental monitoring on water quality, construction noise level at selected noise sensitive receivers, and Contractor’s environmental performance auditing in the aspects of construction dust, construction noise, water quality, waste management, landscape and visual and ecology.

A5. A summary of the environmental monitoring and audit works undertaken in the reporting period are summarized in Table I.

A6. No construction noise monitoring was conducted during the reporting period since there are no Contract -related construction activities undertaken within a radius of 300m from the monitoring locations. No Action Level exceedance was recorded during the reporting period.

A7. Water Quality Monitoring was conducted as schedule in the reporting period. Seven hundred and forty-four (744) action level exceedances and six hundred and eleven (611) limit level exceedances of Suspended Solid were recorded in the reporting period. Summary of exceedances could be referring to Appendix G.

A8. All Action and Limit Level exceedance was concluded to be unrelated to the Project. Details of the exceedance could be referring to Appendix O of the corresponding Monthly EM&A Report.

A9. Four hundred and twenty-four (424) times of landfill gas monitoring were conducted in the reporting period. No action or limit level exceedance was recorded in the reporting period.

|

Environmental Monitoring works |

Frequency |

|

Noise Monitoring |

N/A |

|

Water Quality Monitoring |

150 |

|

Landfill Gas Monitoring |

424 |

|

Environmental Site Inspection |

52 |

A10. One environmental complaint was received from the EPD in the reporting period, no notifications of summons and prosecution was received during the reporting period.

A11. There was no change to be reported that may affect the on-going EM&A programme.

1.1.

Background

The Jardine Engineering Corporation, Limited, China State Construction Engineering (Hong Kong) Limited and Acciona Agua, S.A. Trading as AJC Joint Venture (AJCJV) is contracted to carry out the Design, Build and Operate First Stage of Tseung Kwan O Desalination Plant (TKODP) under Contract No. 13/WSD/17 (the Contract).

Acuity Sustainability Consulting Limited (ASCL) is commissioned by AJCJV to undertake the Environmental Team (ET) services as required and/or implied, both explicitly and implicitly, in the Environmental Permit (EP), Environmental Impact Assessment Report (EIA Report) (Register No. AEIAR-192/2015) and Environmental Monitoring and Audit Manual (EM&A Manual) for the Contract; and to carry out the Environmental Monitoring and Audit (EM&A) programme in fulfillment of the EIA Report’s EM&A requirements and Contract No. 13/WSD/17 Specification requirements.

Pursuant to the Environmental Impact Assessment Ordinance (EIAO), the Director of Environmental Protection granted the Environmental Permit (No. EP-01/503/2015) and Variation of Environmental Permit (No. EP-01/503/2015/A) to Water Supplies Department (WSD); and granted the Further Environmental Permit (No. FEP- 01/503/2015/A) to AJCJV for the Contract.

1.2.

The Reporting Scope

This is the 3rd Annual EM&A Review Report for the Project which summarizes the key findings of the EM&A programme during the reporting period from 1 May 2022 to 30 April 2023.

1.3.

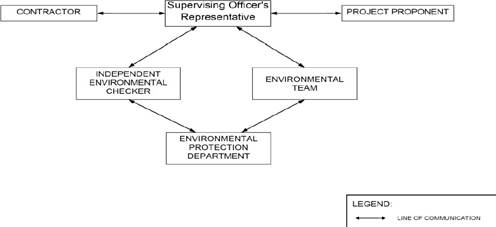

Contract Organization

The Contract Organization structure for Construction Phase is presented in Figure 1.1 and contact details of the key personnel are presented in Table 1.1 below:

|

Party |

Position |

Name |

Telephone no. |

|

Project Proponent (WSD) |

SE/CM2 |

Benny Lam |

2634-3573 |

|

Supervising Officer (Binnies Hong Kong Limited) |

Project Manager |

Christina Ko |

2608-7302 |

|

Chief Resident Engineer |

Roger Wu |

6343-1002 |

|

|

The Jardine Engineering Corporation, Limited, China State Construction Engineering (Hong Kong) Limited and Acciona Agua, S.A. Trading |

Project Manager |

Stephen Yeung |

2807-4665 |

|

Environmental Monitoring Manager |

Brian Kam |

9456-9541 |

|

|

Acuity Sustainability Consulting Limited |

Environmental Team Leader (ETL) |

Jacky Leung |

2698-6833 |

|

ANewR Consulting Limited |

Independent Environmental Checker (IEC) |

Louis Kwan |

2618-2831 |

1.4.

Summary of Construction Works

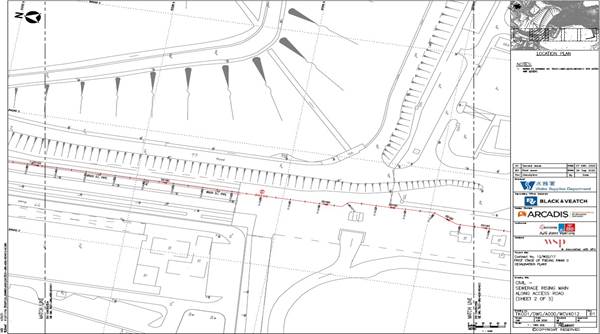

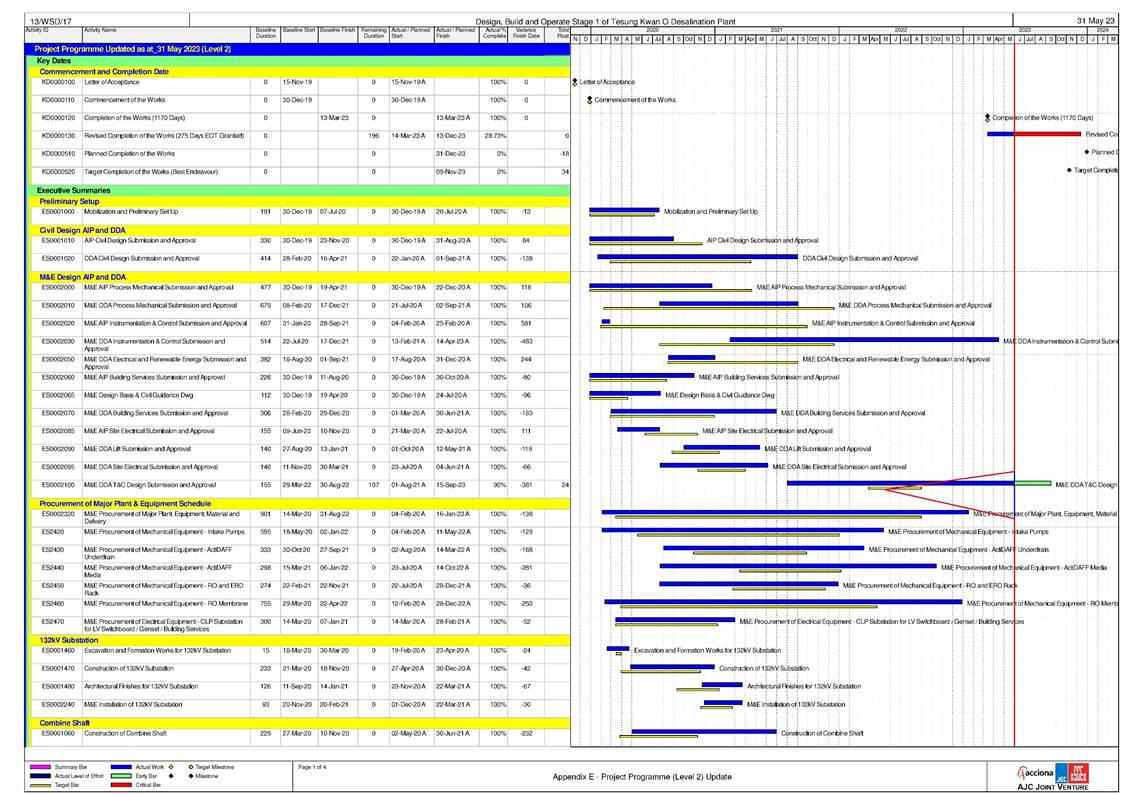

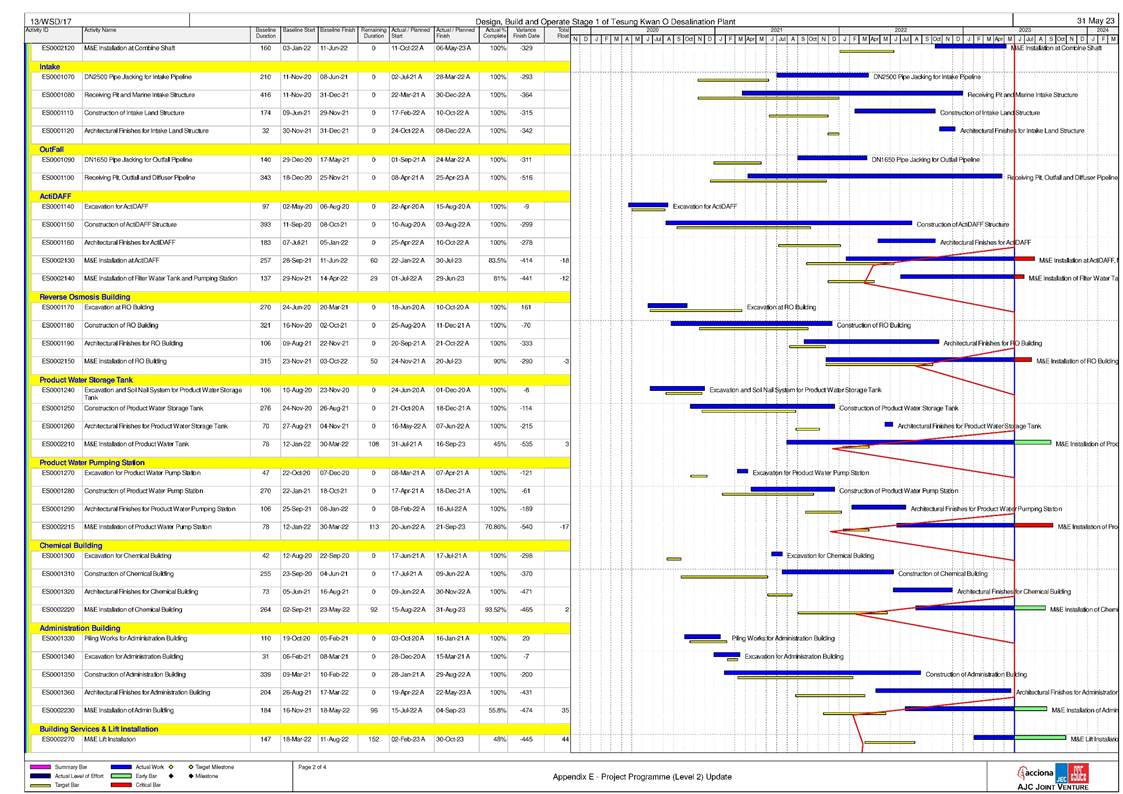

The construction programme is presented in Appendix A. Detail of the major construction activities undertaken could be referred to Section 1.4 in each monthly EM&A Report.

The status for all environmental aspects is presented in Table 1.2.

|

Parameters |

Status |

|

Water Quality |

|

|

Baseline Monitoring under EM&A Manual |

The baseline water quality monitoring was conducted between 12 May 2020 to 6 Jun 2020 |

|

Impact Monitoring |

On-going |

|

Noise |

|

|

Baseline Monitoring |

The baseline noise monitoring result has been reported in Baseline Monitoring Report and submitted to EPD under EP Condition 3.4. |

|

Impact Monitoring |

On-going |

|

Waste Management |

|

|

Mitigation Measures in Waste Management Plan |

On-going |

|

Environmental Audit |

|

|

Site Inspection covering Measures of Air Quality, Noise Impact, Water Quality, Waste, Ecological Quality, Fisheries, Landscape and Visual |

On-going |

Other than the EM&A work by ET, environmental briefings, trainings and regular environmental management meetings were conducted, in order to enhance environmental awareness and closely monitor the environmental performance of the contractors.

The EM&A programme has been implemented in accordance with the recommendations presented in the approved EIA Report and the EM&A Manual. A summary of implementation status of the environmental mitigation measures for the construction phase of the Contract during the reporting period is provided in Appendix C.

2.1.

Monitoring Requirements

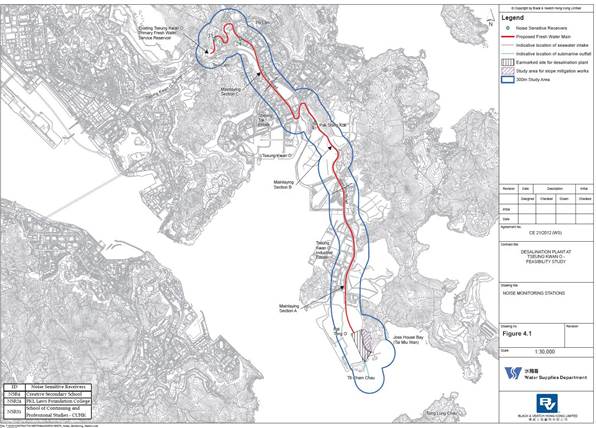

To ensure no adverse noise impact, noise monitoring is recommended to be carried out within 300m radius from the nearby noise sensitive receivers (NSRs), during construction phase. The NSRs selected as monitoring station are (i) NSR4 - Creative Secondary School, (ii) NSR24 - PLK Laws Foundation College, and (iii) NSR31 - School of Continuing and Professional Studies - CUHK respectively.

2.2.

Monitoring Locations

The monitoring locations were normally made at a point 1m from the exterior of the NSRs building façade and be at a position 1.2m above the ground. A correction of +3dB(A) was made to the free-field measurements.

According to the environmental findings detailed in the EIA report and Baseline Monitoring Report, the designated locations for the construction noise monitoring are listed in Table 2.1 below.

|

NSR ID |

Noise Sensitive Receivers |

Monitoring Location |

Position |

|

NSR 4 |

Creative Secondary School |

Roof Floor |

1 m from facade |

|

NSR 24 |

PLK Laws Foundation College |

Pedestrian Road on Ground Floor |

Free field |

|

NSR 31 |

School of Continuing and Professional Studies - CUHK |

Roof Floor |

1 m from facade |

Three noise monitoring locations for impact monitoring at the nearby sensitive receivers are shown in Figure 2.1-2.3.

|

|

|

Figure 2.1 NSR4

Creative Secondary School |

|

|

|

Figure 2.2 NSR24 PLK Laws Foundation College |

|

|

|

Figure 2.3 NSR31

School of Continuing and Professional Studies - CUHK |

2.3.

Monitoring Parameter, frequency and duration

Construction noise level were measured in terms of the A-weighted equivalent continuous sound pressure level (LAeq). Leq 30min was used as the monitoring parameter for the time period between 0700 and 1900 on normal weekdays. Table 2.2 summarizes the monitoring parameters, frequency, and duration of the impact noise monitoring.

|

Time |

Duration |

Interval |

Parameters |

|

Daytime: 0700-1900 |

Day time: 0700-1900 (during normal weekdays) |

Continuously in Leq 5min/Leq 30min (Average of 6 consecutive Leq 5min) |

Leq 30min

L10 30min & L90 30min |

2.4.

Impact Monitoring Methodology

The monitoring methodology and QA/QC procedure could be referring to Section 2.3 of the Monthly EM&A Report.

2.5.

Action and Limit

Levels

The Action/Limit Levels are in line with the criteria of Practice Note for Professional Persons (ProPECC PN 2/93) “Noise from Construction Activities - Non-statutory Controls” and Technical Memorandum on Environmental Impact Assessment Process issued by HKSAR Environmental Protection Department [“EPD”] under the Environmental Impact Assessment Ordinance, Cap 499, S.16 are presented in Table 2.3.

|

Time Period |

Action |

Limit (dB(A)) |

|

0700-1900 on normal weekdays |

When one documented complaint is received from any one of the noise sensitive receivers |

- 70 dB(A) for school and - 65 dB(A) during examination period |

Notes: Limits specified in the GW-TM

and IND-TM for construction and operation noise,

respectively.

If exceedances were found during noise monitoring, the actions in accordance with the Event and Action Plan shall be carried out according to Appendix E.

2.6.

Monitoring Results and Observations

Referring to EM&A manual Section 4.1.2, the impact noise monitoring should be carried out when there are Contract-related construction activities undertaken within a radius of 300m from the monitoring stations. No monitoring station was located within a radius of 300m of the Contract site as shown in Figure 2.4, no impact monitoring for noise impact was conducted in the reporting period.

In accordance with the recommendations of the EIA, water quality EM&A is required during dredging for the submarine pipelines and, during operation phase. In addition, baseline water quality monitoring was prior to the commencement of marine construction activities.

The following Section provides details of the water quality monitoring to be undertaken by the Environmental Team (ET) to verify the distance of sediment and brine plume dispersion and to identify whether the potential exists for any indirect impacts to occur to ecological sensitive receivers.

Water quality monitoring for the Contract can be divided into the following stages:

- Dredging activities during construction phase;

- Discharge of effluent from main disinfection during construction phase;

- Operation phase - first year upon commissioning; and,

- Continuous monitoring of effluent quality.

In addition, the marine works contractor is required to complete a silt curtain efficiency test for the combined use of floating silt curtain type and cage type silt curtain for dredging at seawater intake to confirm the silt curtain reduction efficiency assumptions of the assessment. The details of testing plan together with the silt curtain deployment plan shall be submitted by the ET to seek approval from the IEC and EPD.

3.1.

Water Quality Parameters

The parameters that have been selected for measurement in situ and in the laboratory are those that were either determined in the EIA to be those with the most potential to be affected by the construction works or are a standard check on water quality conditions. Parameters to be measured in the impact water quality monitoring are listed in Table 3.1.

|

Parameters |

Unit |

Abbreviation |

|

In-situ measurements |

||

|

Dissolved oxygen |

mg/L |

DO |

|

Temperature |

oC |

- |

|

pH |

- |

- |

|

Turbidity |

NTU |

- |

|

Salinity |

0/00 |

- |

|

Laboratory measurements |

||

|

Suspended Solids |

mg/L |

SS |

NOTE 1: Monitoring of TRC will be

conducted when cleaning

and sterilization of the new freshwater main is carried

out.

In addition to the water quality parameters, other relevant data was measured and recorded in Water Quality Monitoring Logs, including the location of the sampling stations, water depth, time, weather conditions, sea conditions, tidal stage, current direction and velocity, special phenomena and work activities undertaken around the monitoring and works area that may influence the monitoring results.

3.2.

Monitoring Equipment

The monitoring methodology, monitoring equipment and QA/QC procedure could be referring to Section 3.1.2 - 3.1.4 of the Monthly EM&A Report.

3.3.

Monitoring Location

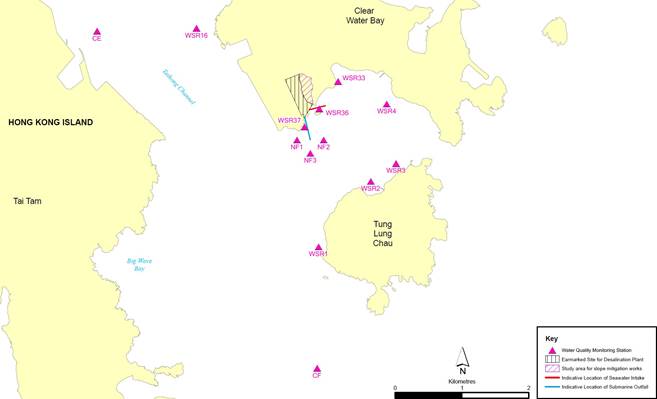

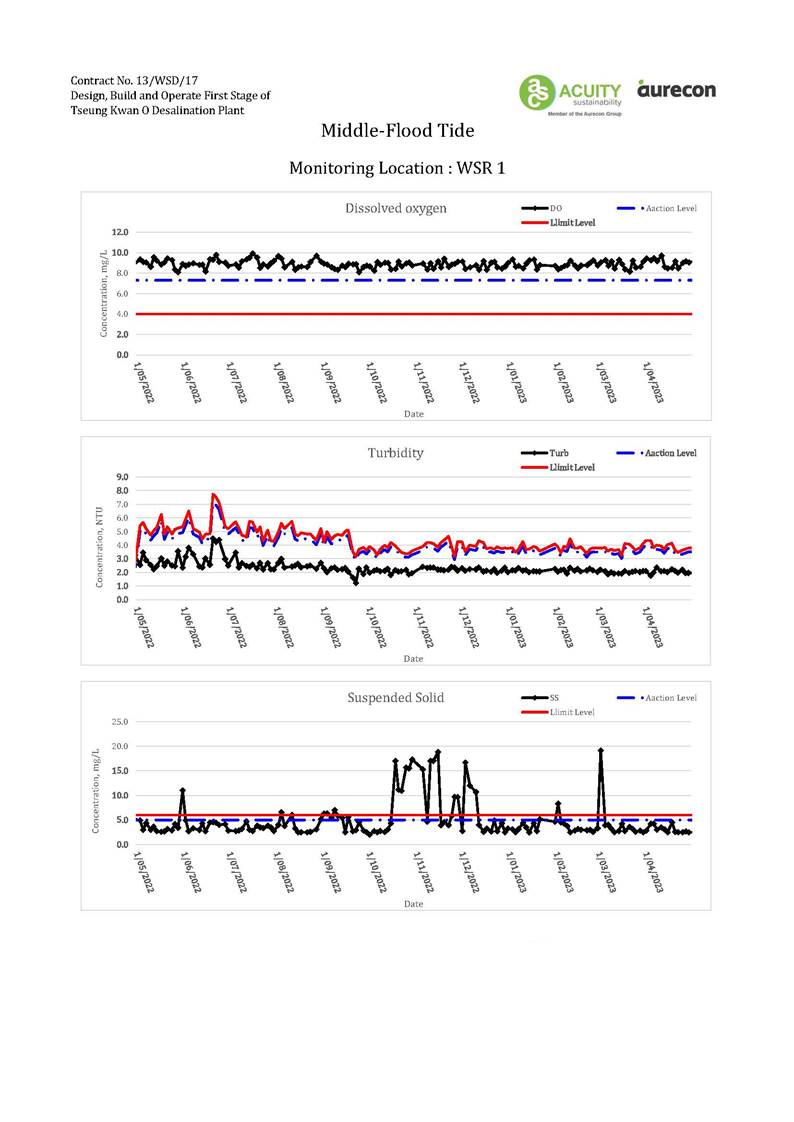

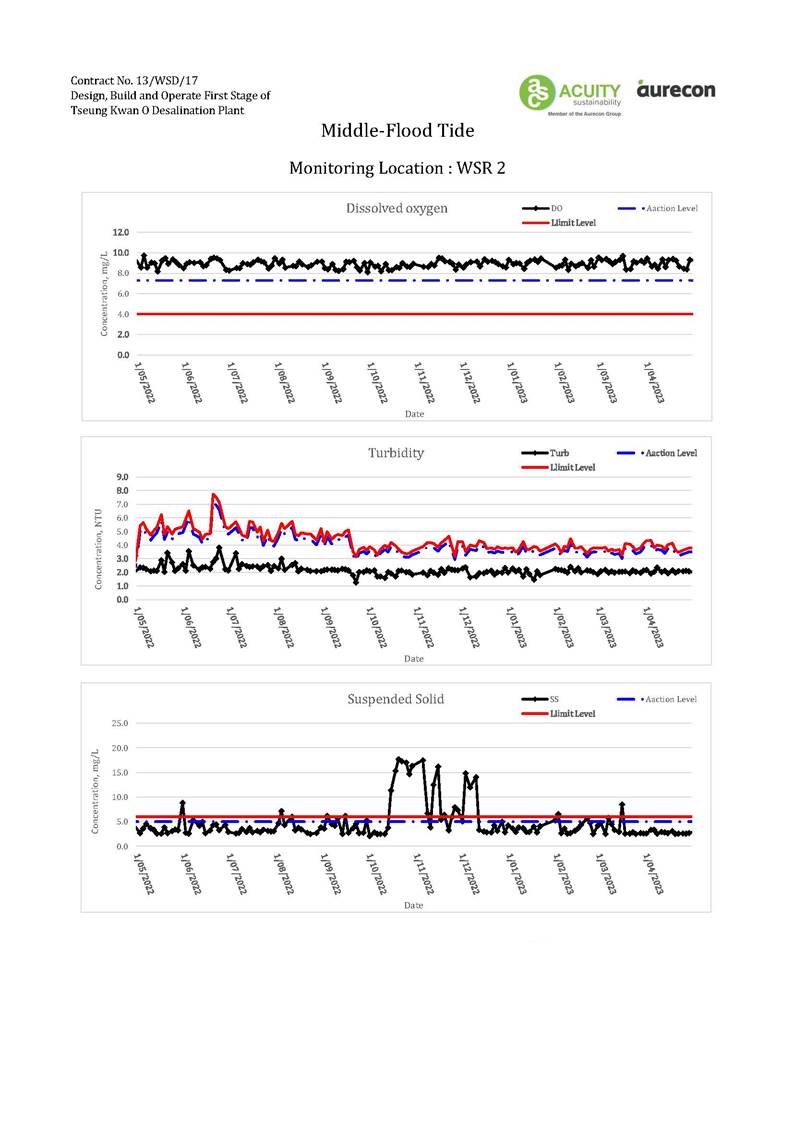

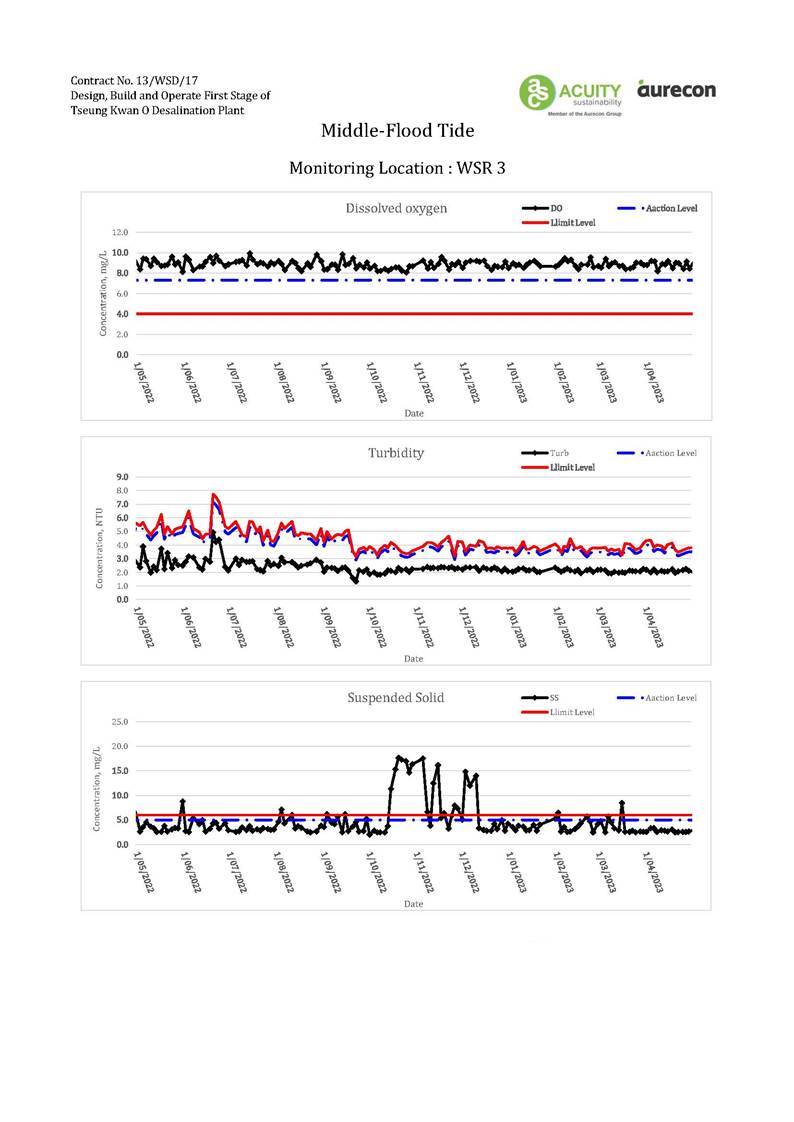

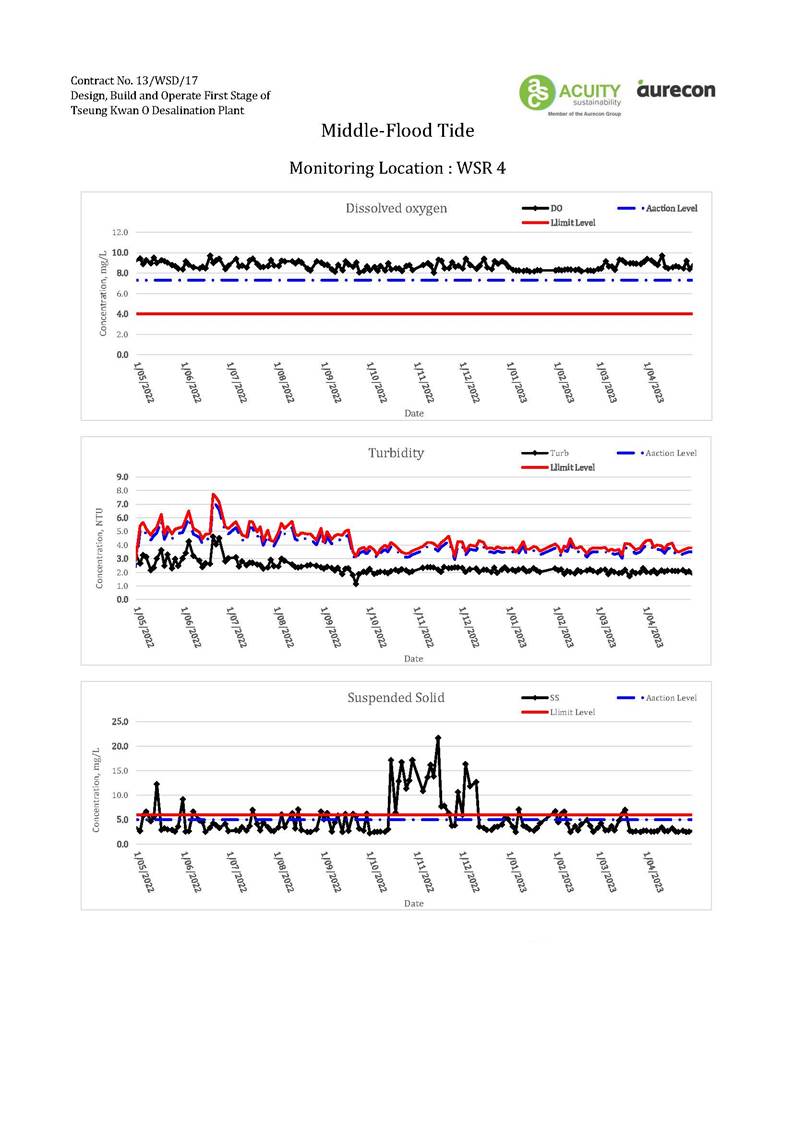

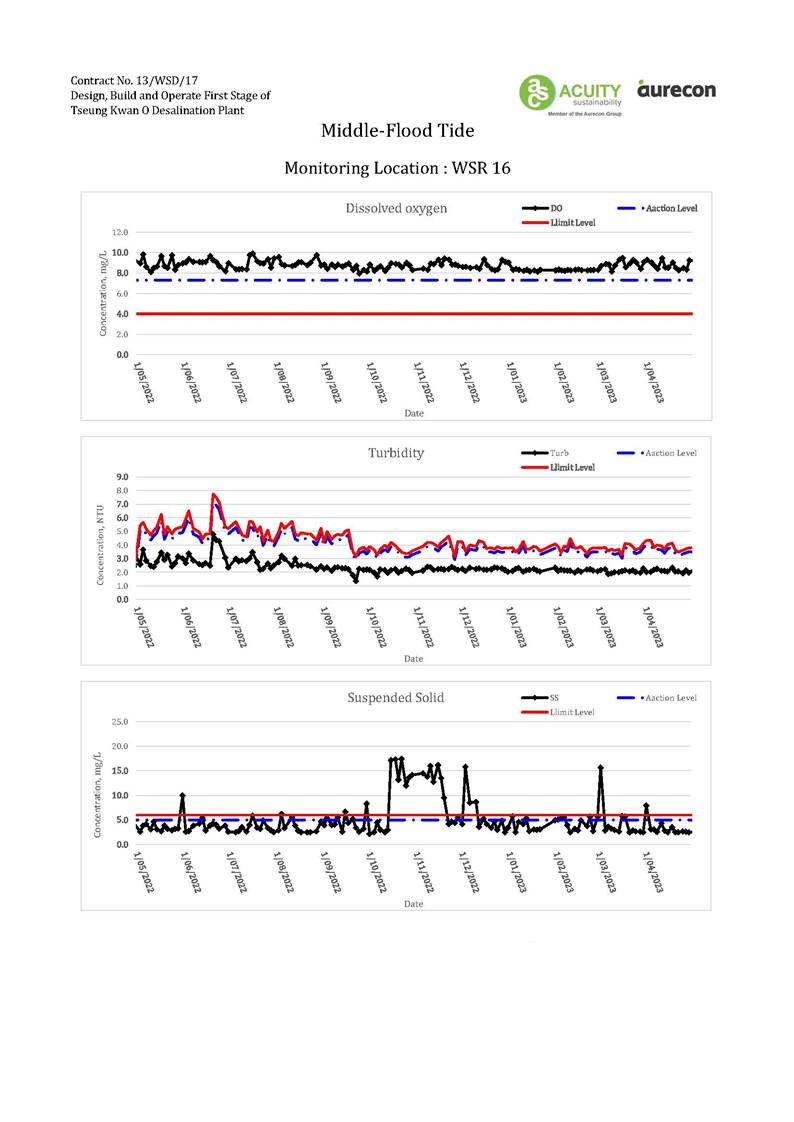

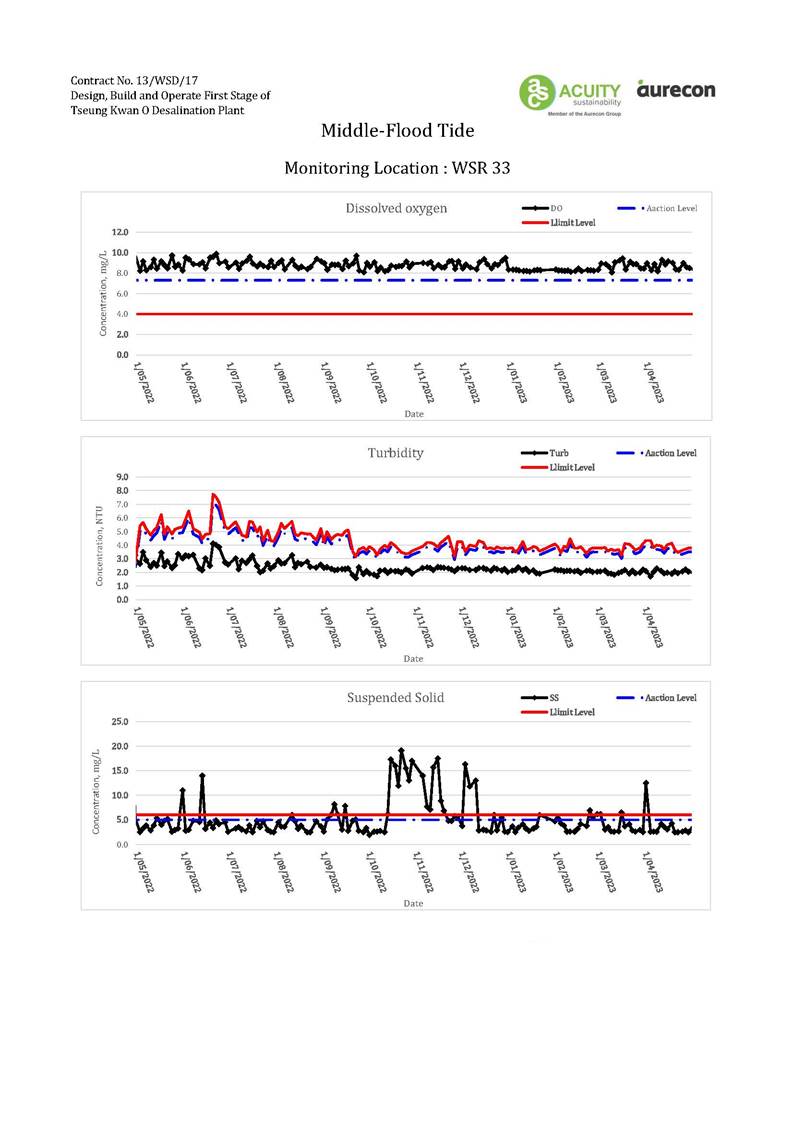

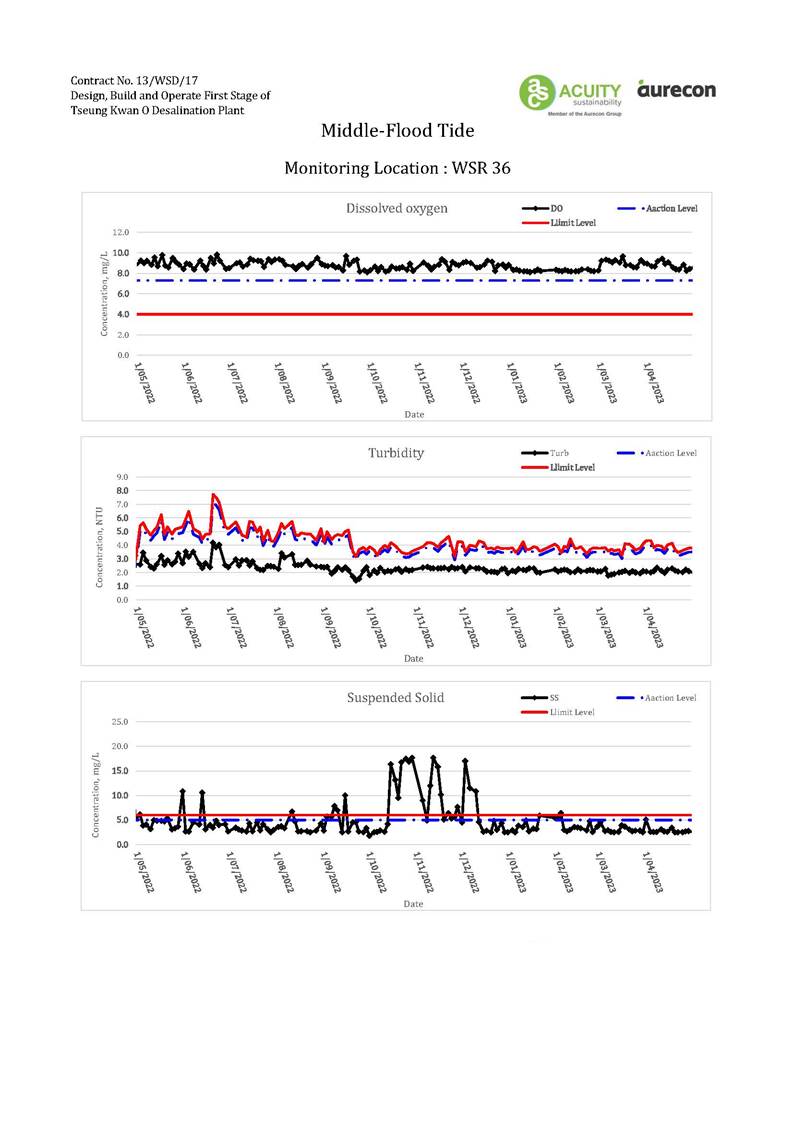

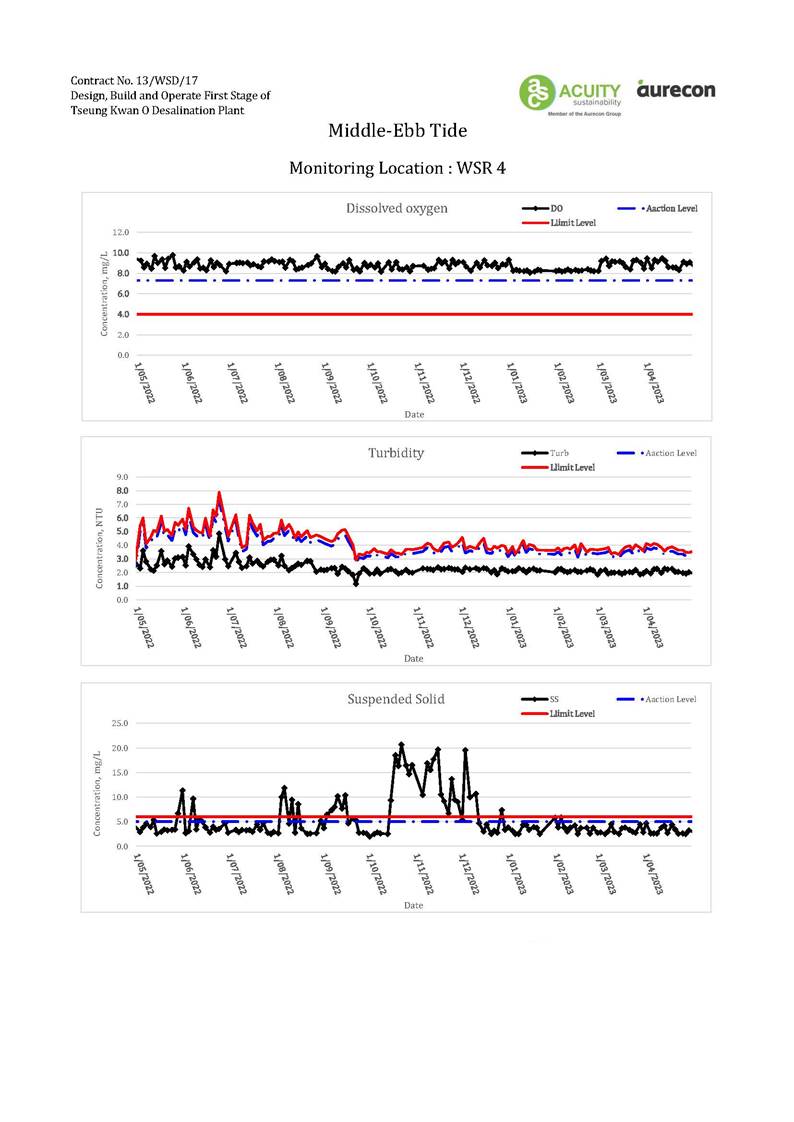

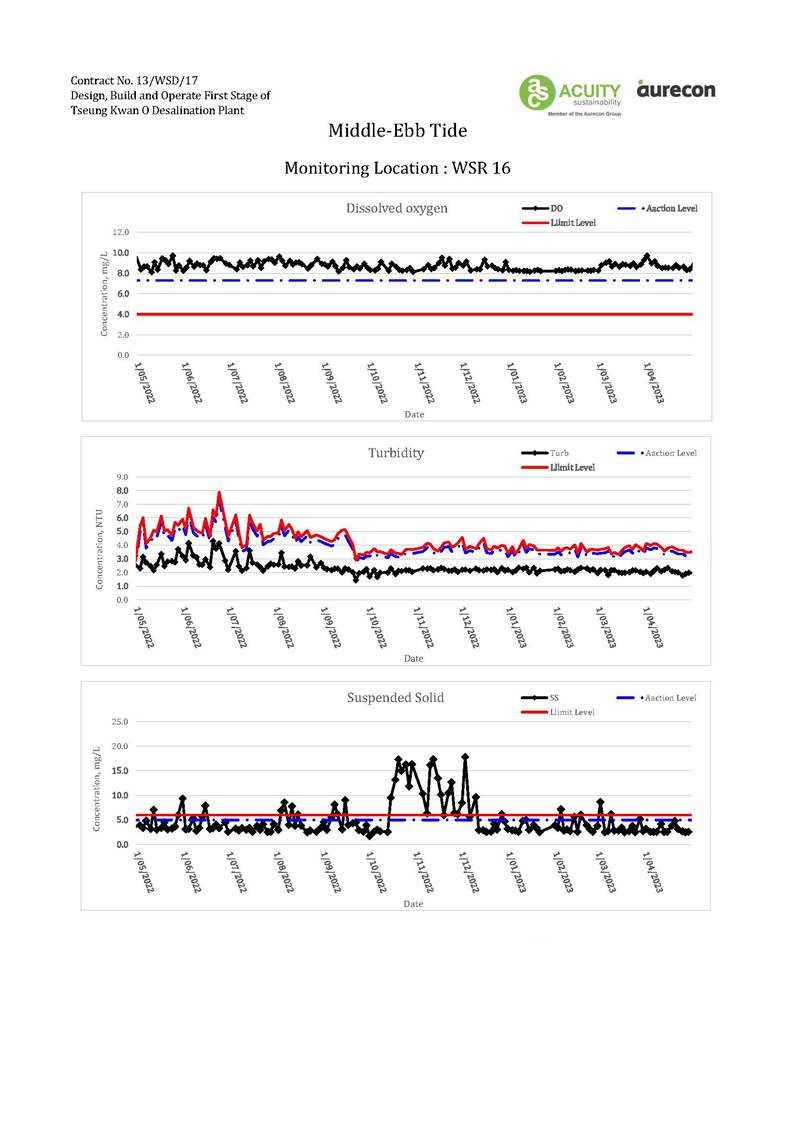

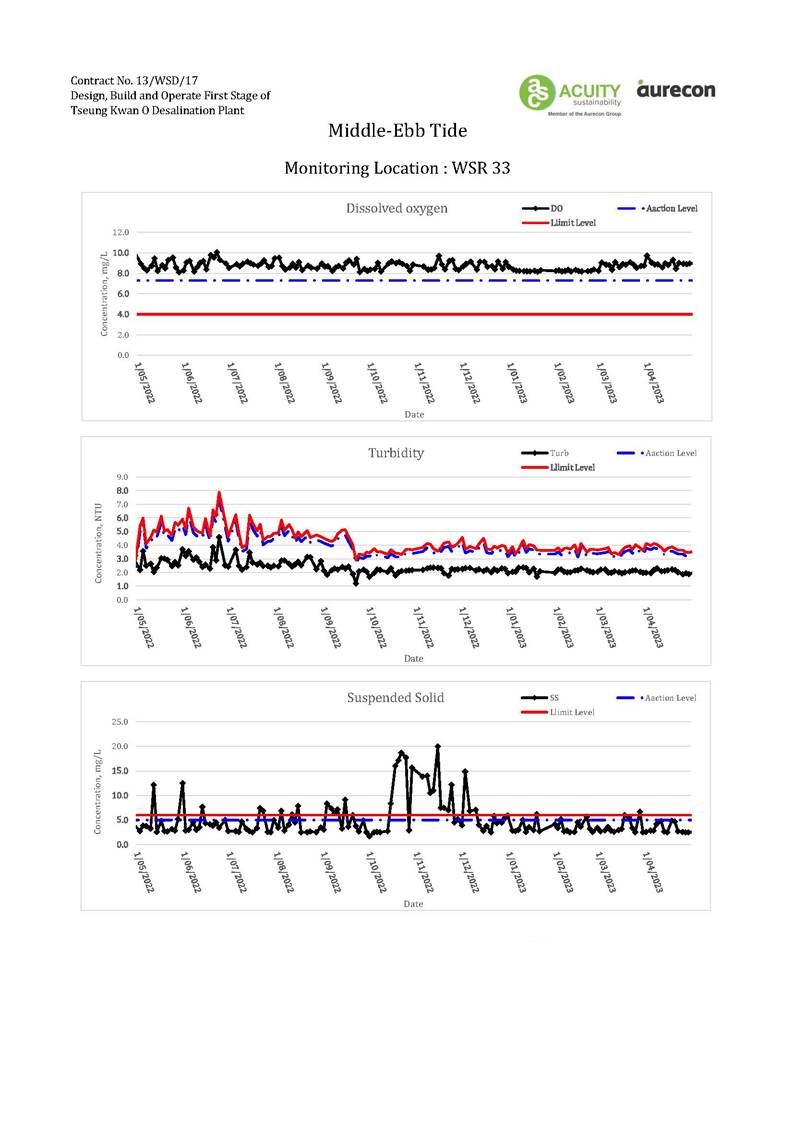

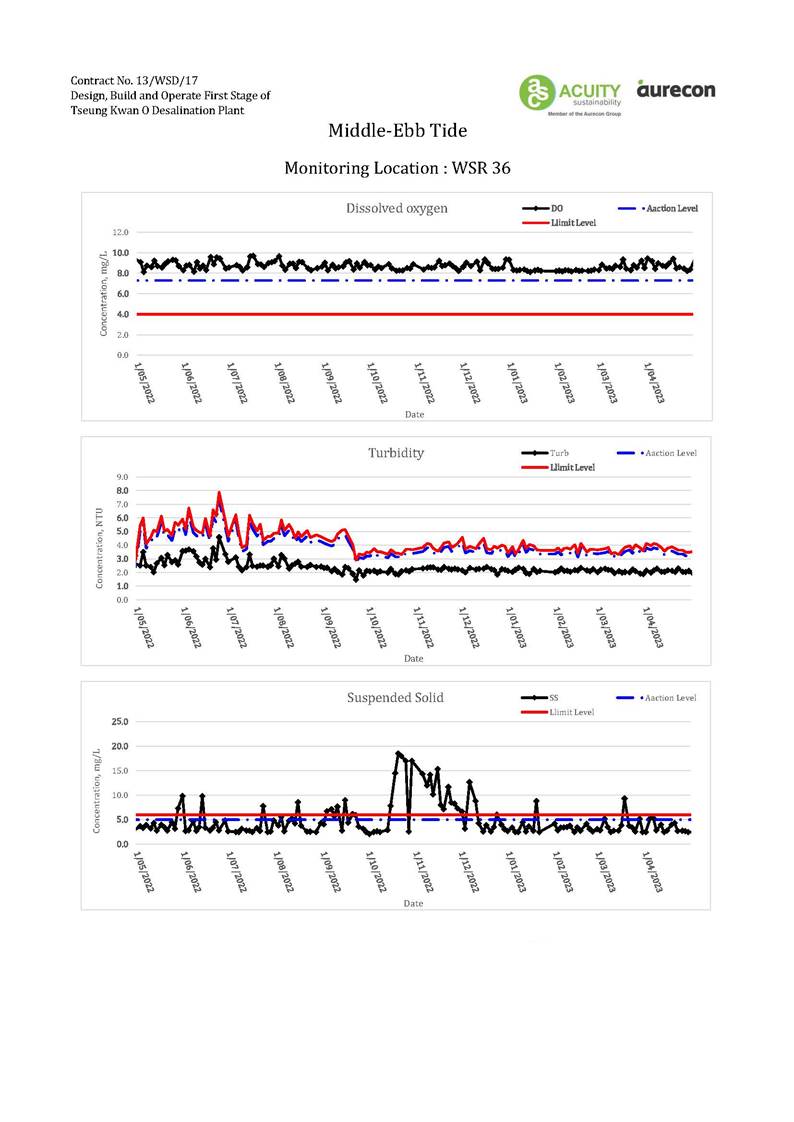

The impact water quality monitoring locations are in accordance with the EM&A Manual and detailed in Table 3.3 below.

|

Station |

Easting |

Northing |

Description |

|

CE |

843550 |

815243 |

Upstream control station at ebb tide |

|

CF |

846843 |

810193 |

Upstream control station at flood tide |

|

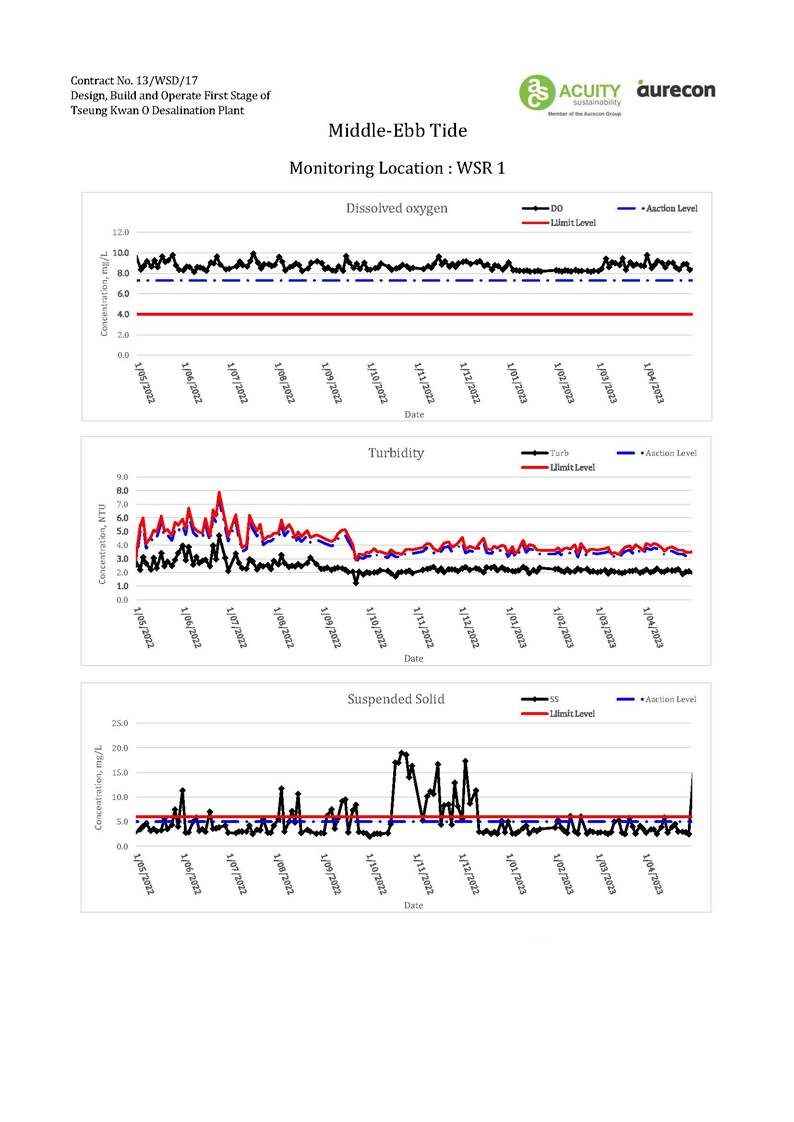

WSR1 |

846864 |

812014 |

Ecological sensitive receiver at Tung Lung Chau |

|

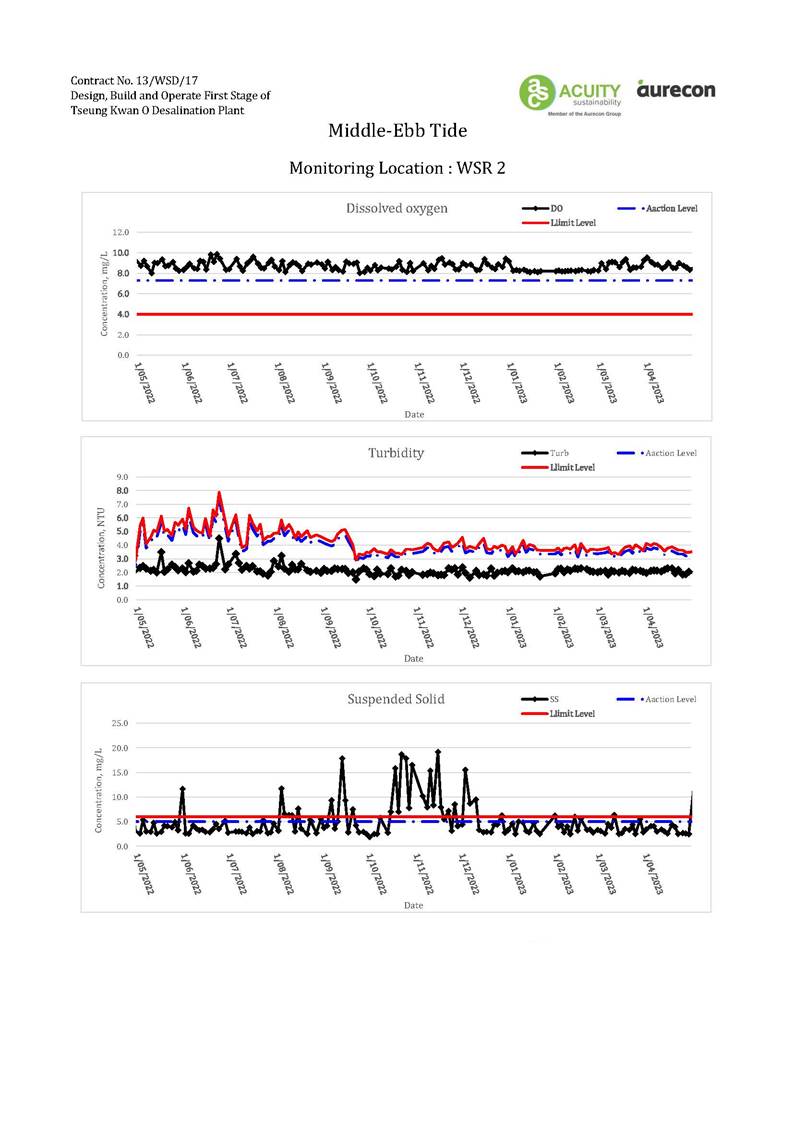

WSR2 |

847645 |

812993 |

Fisheries sensitive receiver at Tung Lung Chau |

|

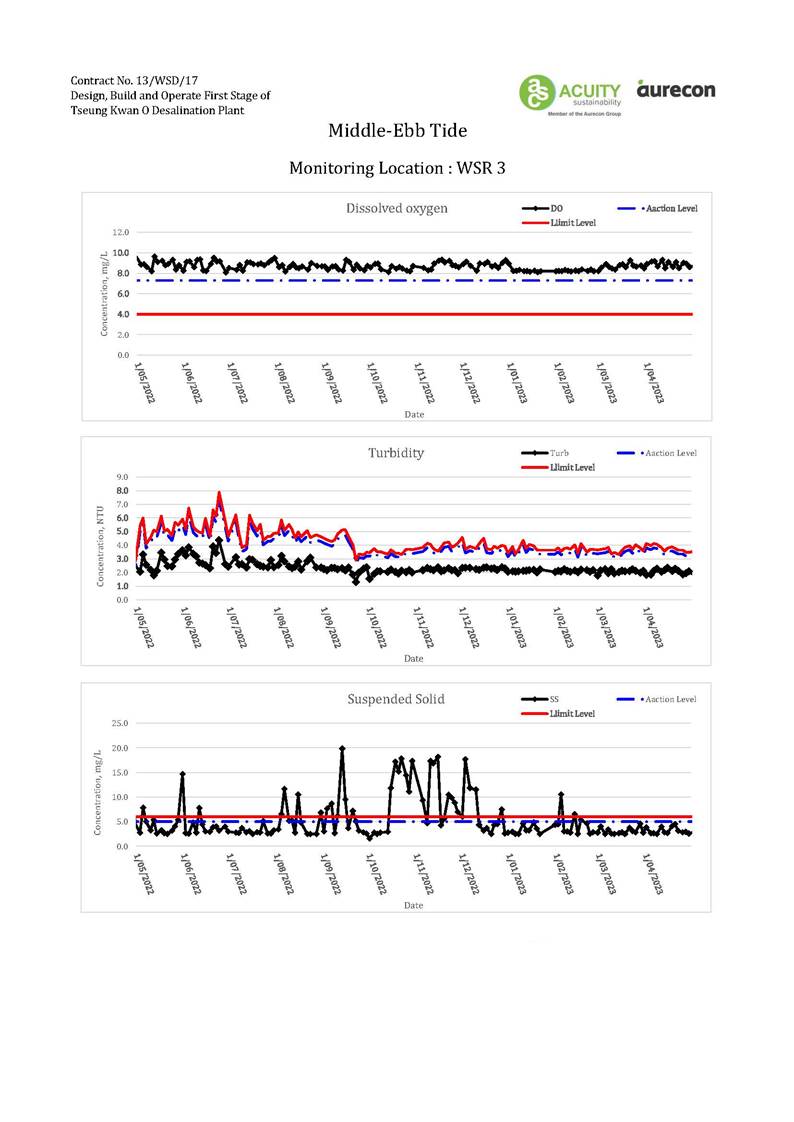

WSR3 |

848023 |

813262 |

Ecological sensitive receiver at Tung Lung Chau |

|

WSR4 |

847886 |

814154 |

Ecological sensitive receiver at Tai Miu Wan |

|

WSR16 |

845039 |

815287 |

Ecological sensitive receiver at Fat Tong Chau |

|

WSR33 |

847159 |

814488 |

Ecological sensitive receiver at Tai Miu Wan |

|

WSR36 |

846878 |

814081 |

Ecological sensitive receiver at Kwun Tsai |

|

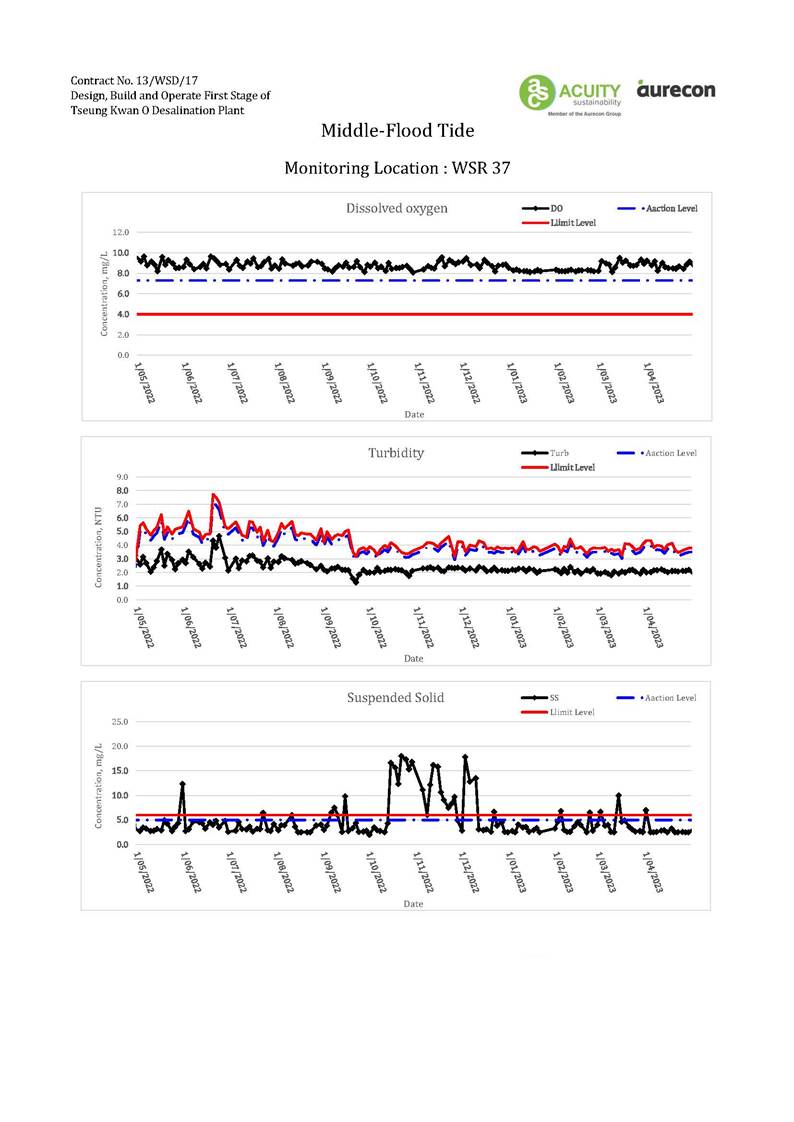

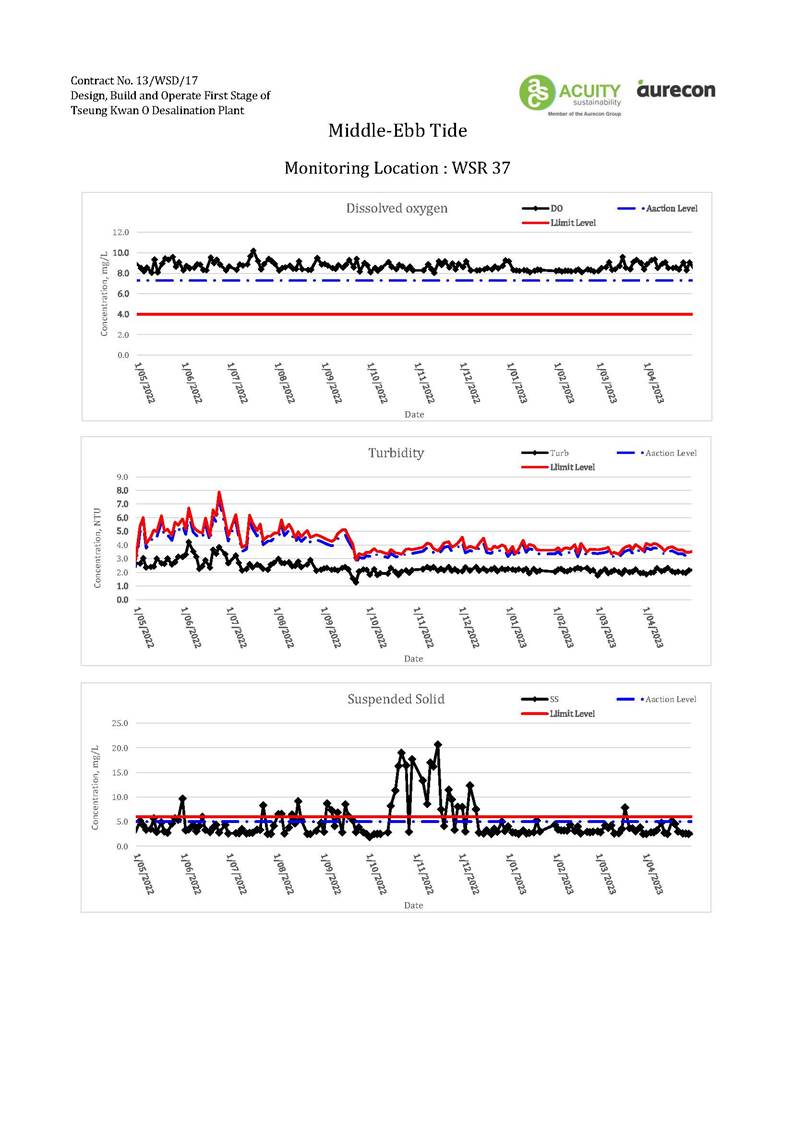

WSR37 |

846655 |

813810 |

Ecological sensitive receiver at Tit Cham Chau |

|

NF1 |

846542 |

813614 |

Edge of mixing zone, ~ 200m west of outfall diffuser |

|

NF2 |

846942 |

813614 |

Edge of mixing zone, ~ 200m east of outfall diffuser |

|

NF3 |

846742 |

813414 |

Edge of mixing zone, ~ 200m south of outfall diffuser |

WSR1 to WSR37 were identified in accordance with Annex 14 of the EIAO-TM as well as Clause 3.4.4.2 of the Environmental Impact Assessment Study Brief for Desalination Plant at Tseung Kwan O (No. ESB-266/2013). WSR1 to WSR3 are sited near the Tung Lung Chau Fish Culture Zone; WSR16 and WSR36 are sited near the coral assemblages along the

coastlines of Fat Tong Chau and Kwun Tsai respectively; WSR 4 and WSR33 are sited near the Coastal Protection Area and coral assemblages in waters of Tai Miu Wan; WSR37 is sited near the fisheries resource including spawning and nursery grounds at the coastal water of Tit Cham Chau.

3.4.

Action and Limit

levels

The Action and Limit Levels have been set based on the derivation criteria specified in the EM&A Manual. Based on the baseline water quality monitoring data and the derivation criteria, the Action/Limit Levels have been derived and are presented in Table 3.4.

|

Parameters |

Action |

Limit |

|

Construction Phase Impact

Monitoring |

||

|

DO in mg/L |

Surface and Middle 7.30 mg L-1 Bottom 7.31 mg L-1 Tung Lung Chau Fish Culture Zone 5.1 mgL-1 or level at control station (whichever the lower) |

Surface and Middle 4 mg

L-1 Bottom 2 mg L-1 Tung Lung Chau Fish Culture Zone 5.0 mgL-1 or level at control station (whichever the lower) |

|

SS in mg/L (Depth- averaged) |

5.00 mg L-1 or 20% exceedance of value at any impact station compared with corresponding data from control station |

6.00 mg L-1 or 30% exceedance of value at any impact station compared with corresponding data from control station |

|

Turbidity in NTU (Depth-averaged) |

2.41 NTU or 20% exceedance of value at any impact station compared with corresponding data from control station |

2.84 NTU or 30% exceedance of value at any impact station compared with corresponding data from control station |

Notes:

i. "Depth-averaged" is calculated by taking the arithmetic means

of reading of all three depths.

ii. For DO, non-compliance of the water quality limits

occurs when monitoring result is lower

than the limits.

iii. For Turbidity, SS, iron and Salinity,

non-compliance of the water quality

limits occurs when monitoring result is higher than the limits.

iv. For the Action and Limit Levels adopted during

First-year Operation Phase

Monitoring, further review

would be made according to the EM&A Manual during Operation Phase.

3.5.

Monitoring Programme

The ET of the Contract had conducted the impact water quality monitoring between 1 May 2022 to 30 April 2023 at the ten designated monitoring stations at waters near TKO in accordance with the EM&A Manual and Contract Specification respectively.

3.6.

Monitoring results and observations

The impact water quality monitoring at the designated locations were conducted by the ET as scheduled in the reporting period. The graphical presentation of the water quality monitoring result was shown in Appendix D.

Seven hundred and forty-four (744) of the general water quality monitoring results of SS obtained had exceeded the Action level. Six hundred and eleven (611) of the general water quality monitoring results of SS obtained during the reporting period had exceeded the Limit Level.

Details of the exceedance could be referring to Appendix O of the Monthly EM&A Report.

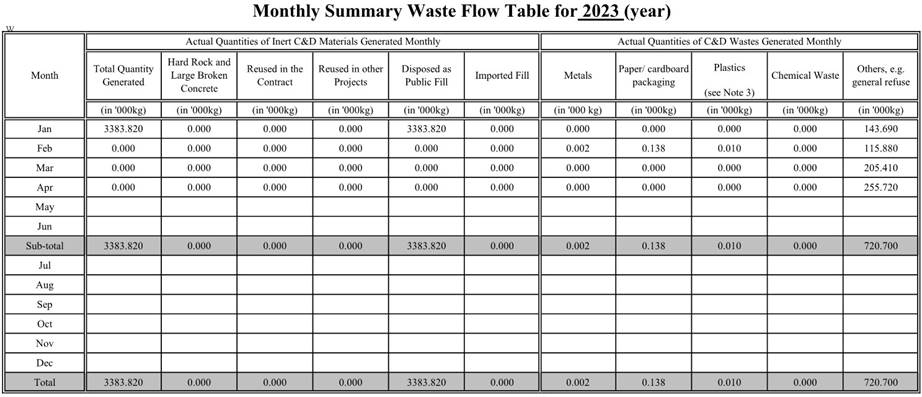

The waste generated from this Project includes inert construction and demolition (C&D) materials, and non-inert C&D materials. Non-inert C&D materials are made up of general refuse, vegetative wastes and recyclable wastes such as plastics and paper/cardboard packaging waste. Steel materials generated from the project are also grouped into non-inert C&D materials as the materials were not disposed of with other inert C&D materials. Details of cumulative waste management data are presented as a waste flow table in Appendix F.

5.1.

Monitoring Requirement

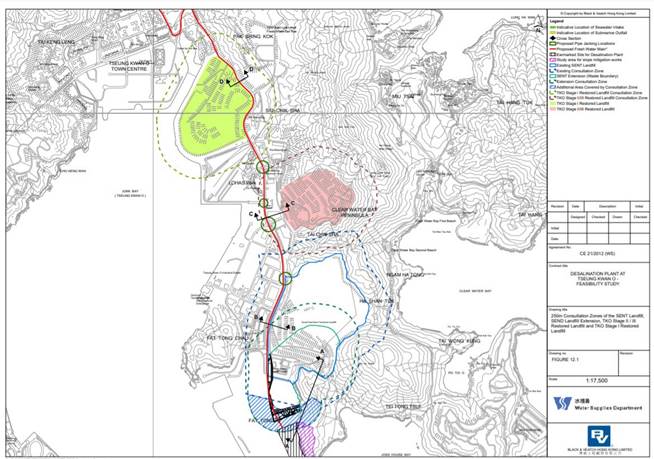

In according with Section 11 of the EM&A Manual, monitoring of landfill gas is required for construction works within the 250m Consultation Zone. Part of the desalination plant and the indicative area of natural slope mitigation works fall within the SENT Landfill Extension Consultation Zone; and part of the 1,200 mm diameter freshwater mains along Wan Po Road falls within the SENT Landfill and SENT Landfill Extension Consultation Zones, TKO Stage II/III Restored Landfill and TKO Stage I Restored Landfill Consultation Zones.

Since part of the desalination plant (Wan Po Road and MIC compound/Basketball Court) and the indicative area of natural slope mitigation works fall within the SENT Landfill Extension Consultation Zone in this contract (Figure 5.1), landfill gas monitoring would be required for Wan Po Road and MIC compound/Basketball Court (Figure 5.2) if excavations were conducted at more than 300mm deep. Although SENT Landfill Extension has commenced operation since November 2021, no excavation works were conducted at MIC compound/Basketball Court. Hence no landfill gas monitoring would be scheduled for MIC compound/Basketball Court at the current stage.

5.2.

Monitoring Parameters

LFG monitoring was carried out to identify any migration between the landfill and the Contract and to ensure the safety of the construction, operation and maintenance personnel working on-site, visitors and any other person within the Contract area.

The following parameters were monitored:

- Methane

- Oxygen

- Carbon Dioxide

- Barometric Pressure

5.3.

MONITORING EQUIPMENT

Landfill Gas monitoring was carried out using intrinsically safe, portable multi-gas monitoring instruments. Detail of monitoring equipment used in the reporting period could be referred to Section 5.10 of the corresponding Monthly EM&A Report.

5.4.

Monitoring results and observations

Four hundred and twenty-four (424) times of landfill gas monitoring were conducted in the reporting period. No action or limit level exceedance was recorded in the reporting period.

Action and Limit Level are provided in Table 5.1.

|

Parameters |

Level |

Action |

|

Oxygen (O2) |

Action Level <

19% O2 Limit Level < 19% O2 |

Ventilate trench/void to restore

O2 to > 19% Stop works |

|

|

|

Evacuate personnel/prohibit entry |

|

|

|

Increase

ventilation to restore

O2 to > |

|

|

|

19% |

|

Methane (CH4) |

Action Level >10% LEL |

Post "No Smoking" signs |

|

|

|

Prohibit hot works |

|

|

|

Increase ventilation to restore CH4 to |

|

|

|

<10% LEL |

|

|

Limit Level >20% LEL |

Stop works |

|

|

|

Evacuate personnel/prohibit entry |

|

|

|

Increase ventilation to restore |

|

|

|

CH4 to<10% LEL |

|

Carbon Dioxide (CO2) |

Action Level >0.5% CO2 |

Ventilate to restore CO2 to < 0.5% |

|

|

Limit Level >1.5% CO2 |

Stop works |

|

|

|

Evacuate personnel / prohibit entry |

|

|

|

Increase ventilation to restore CO2 to |

|

|

|

<0.5% |

6.

SUMMARY OF EXCEEDANCE, COMPLAINTS, NOTIFICATION

OF SUMMONS AND

Prosecutions

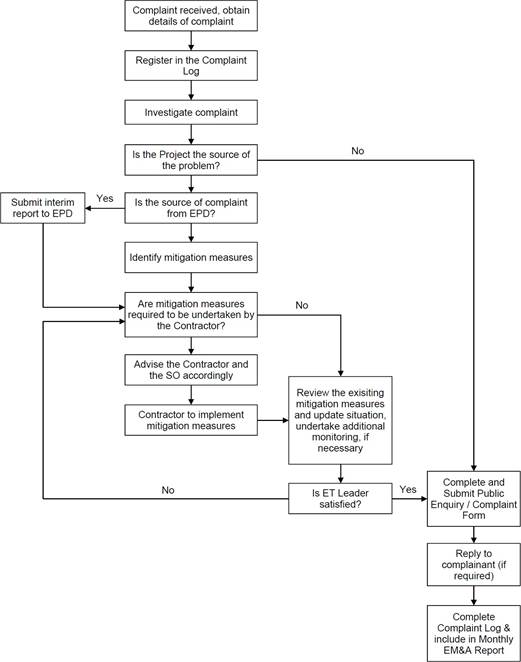

The Environmental Complaint Handling Procedure is shown in below Figure 6.1:

No noise monitoring was conducted during the reporting period since there are no Contract-related construction activities undertaken within a radius of 300m from the monitoring locations.

Seven hundred and forty-four (744) of the general water quality monitoring results of SS obtained had exceeded the Action level. Six hundred and eleven (611) of the general water quality monitoring results of SS obtained during the reporting period had exceeded the Limit Level.

Details of the exceedance could be referring to Appendix O of the corresponding Monthly Report.

Four hundred and twenty-four (424) times of landfill gas monitoring were conducted in the reporting period. No action or limit level exceedance was recorded in the reporting period.

One environmental complaint was received from EPD on 22 July 2022 in the reporting period. Detailed information could be referred to the Monthly EM&A Report in July 2022. No notification of summons and prosecution was received in the reporting period. Summary of complaint log are presented in Appendix J.

Site inspections were carried out on a weekly basis to monitor the implementation of proper environmental pollution control and mitigation measures under the Contract. In the reporting period, site inspections were carried out from May 2022 to April 2023.

Fifty-two (52) site inspection were carried out in the reporting period.

Environmental deficiencies were observed during weekly site inspection. Key observations during the site inspections and during the reporting period could be referring to Appendix E and corresponding Monthly Report.

According to the EIA Study

Report, Environmental Permit, contract documents and EM&A Manual, the

mitigation measures detailed in the documents should be implemented as much as

practical during the reporting period. An updated Implementation Status of

Environmental Mitigation Measures (EMIS) is provided in Appendix C.

This is the 3rd Annual EM&A Review Report for the Project which summarizes the key findings of the EM&A programme during the reporting period from 1 May 2022 to 30 April 2023, in accordance with the EM&A Manual and the requirement under FEP- 01/503/2015/A.

No noise monitoring was conducted in the reporting period due to the over distant monitoring station from the works location, in which construction activities were not undertaken within a radius of 300m from the monitoring locations.

The EM&A works for water quality were conducted during the reporting period in accordance with the EM&A Manual.

Seven hundred and forty-four (744) of the general water quality monitoring results of SS obtained had exceeded the Action level. Six hundred and eleven (611) of the general water quality monitoring results of SS obtained during the reporting period had exceeded the Limit Level. All Action and Limit Level exceedances were unrelated to the project.

Details of the exceedance could be referring to Appendix O of the corresponding Monthly EM&A Report.

Four hundred and twenty-four (424) times of landfill gas monitoring were conducted in the reporting period. No action or limit level exceedance was recorded in the reporting period.

Weekly environmental site inspection was conducted during the reporting period. Minor deficiency was observed during site inspection. The environmental performance of the project was therefore considered satisfactory.

According to the environmental site inspections performed in the reporting period, the Contractor is reminded to pay attention on maintaining proper materials storage, site tidiness and chemical storage on site.

One environmental complaint was received from EPD on 22 July 2022 in the reporting period. Detailed information could be referred to the Monthly EM&A report in July 2022. No notification of summons or prosecution was received in the reporting period.

The ET will keep track on the construction works to confirm compliance of environmental requirements and the proper implementation of all necessary mitigation measures.

Appendix A

Master Programme

Appendix B

Overview of Desalination Plant in Tseung Kwan O

Appendix C

Summary of Implementation Status of Environmental Mitigation

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of

the recommended measures

& main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

Air Quality |

|

|||||||

|

S4.8.1 |

Impervious dust screen or

sheeting will be provided to enclose scaffolding from the ground

floor level of building for construction of superstructure of

the new buildings. |

Land site/ During Construction |

Contractor(s) |

|

ü |

|

Implemented |

Air Pollution Control (Construction Dust) |

|

S4.8.1 |

Impervious sheet

will be provided for skip hoist

for material transport. |

Land site/ During Construction, particularly dry season |

Contractor(s) |

|

ü |

|

NA |

- |

|

S4.8.1 |

The area

where dusty work

takes place should

be sprayed with water or a dust

suppression chemical immediately prior

to, during and immediately after dusty activities as far as practicable. |

Land site/ During Construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S4.8.1 |

All dusty materials should be sprayed

with water or a dust suppression

chemical immediately prior to any loading,

unloading or transfer operation. |

Land site/ During Construction |

Contractor(s) |

|

ü |

|

Implemented, reminder issued |

- |

|

S4.8.1 |

Dropping heights for excavated materials should be controlled to a practical height to

minimize the fugitive dust arising

from unloading. |

Land site/ During Construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S4.8.1 |

During transportation by truck, materials should

not be loaded to a level higher

than the side and tail boards and should

be dampened or covered before transport. |

Land site/ During Construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S4.8.1 |

Wheel washing device should be provided at the exits of the work sites.

Immediately before leaving a construction site, every vehicle shall be washed to

remove any dusty material from its

body and wheels as far as practicable. |

Land site/ During Construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S4.8.1 |

Road sections between

vehicle-wash areas and vehicular entrance

will be paved. |

Land site/ During Construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S4.8.1 |

Hoarding of not less

than 2.4m high from ground

level will be provided along

the length of the

Project Site boundary. |

Land site/ During

construction |

Contractor(s) |

ü |

ü |

|

N/A |

- |

|

S4.8.1 |

Haul roads will be kept clear of dusty materials and will be sprayed

with water so as to maintain the entire road

surface wet at all times. |

Land site/

During construction |

Contractor(s) |

|

ü |

|

Implemented, reminder issued |

- |

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of

the recommended measures

& main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S4.8.1 |

Temporary stockpiles of dusty materials will be either covered entirely by impervious sheets or

sprayed with water to maintain the

entire surface wet all the time. |

Land site/

During construction |

Contractor(s) |

|

ü |

|

Implemented, reminder issued |

- |

|

S4.8.1 |

Stockpiles of more than

20 bags of cement, dry pulverised fuel ash and dusty

construction materials will be covered entirely by impervious sheeting

sheltered on top and 3- sides. |

Land site/ During

construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S4.8.1 |

All exposed

areas will be kept wet always to minimize dust emission. |

Land site/ During

construction |

Contractor(s) |

|

ü |

|

Implemented, reminder issued |

- |

|

S4.8.1 |

Ultra-low-sulphur diesel (ULSD) will be

used for all construction plant

on-site, as defined as diesel fuel containing

not more than 0.005% sulphur by weight) as stipulated in Environment, Transport and

Works Bureau Technical Circular

(ETWB-TC(W)) No 19/2005 on Environmental

Management on Construction Sites. |

Land site/ During construction/ During Operation |

Contractor(s) |

|

ü |

ü |

Implemented |

Environment, Transport and Works Bureau

Technical Circular (ETWB-

TC(W)) No 19/2005 on Environmental Management on Construction Sites |

|

S4.8.1 |

The engine

of the construction equipment during idling

will be switched off. |

Land site/ During

construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S4.8.1 |

Concrete batching plant will be required on site. control measures recommended in the Guidance

Note on a Best Practicable Means

for Cement Works (Concrete Batching Plant)

(BPM 3/2 (93)) will be implemented. The control measures recommended in the Guidance Note on a Best Practicable Means for Cement Works

(Concrete Batching Plant) (BPM 3/2

(93)) will be implemented. |

Land site/

During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S4.8.1 |

Regular maintenance of construction equipment deployed on-site

will be conducted to prevent black smoke emission. |

Land site/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S4.10 |

To ensure proper implementation of the recommended dust mitigation measures and good

construction site practices during

the construction phase, environmental site audits

on weekly basis is recommended throughout the construction period. |

Land site/ During

construction |

Contractor(s)/ ET & IEC |

|

ü |

|

Implemented |

|

Note: D - Design stage C - Construction O - Operation

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

Noise |

||||||||

|

S5.7 |

Only well-maintained plant will be operated on-site and plant will be serviced regularly during

the construction phase. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

A Practical Guide for the Reduction of Noise from |

|

S5.7 |

Silencers or mufflers on construction equipment will be utilised and will be properly maintained during the |

Noise control/ During construction |

Contractor(s) |

|

ü |

|

N/A |

Construction Works |

|

|

construction phase. |

|

|

|

|

|

||

|

S5.7 |

Mobile plant,

if any, will

be sited as far away from NSRs

as possible. |

Noise control/ During construction |

Contractor(s) |

|

ü |

|

N/A |

|

|

S5.7 |

Machines and plant

(such as trucks)

that may be in intermittent use will be shut down between work periods |

Noise control/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

|

|

|

or will be throttled down

to a minimum. |

|

|

|

|

|

||

|

S5.7 |

Plants known to emit noise strongly in one

direction will, wherever possible, be orientated so that the

noise is |

Noise control/ During construction |

Contractor(s) |

|

ü |

|

N/A |

|

|

|

directed away from the nearby

NSRs. |

|

|

|

|

|

||

|

S5.7 |

Material stockpiles and other structures will be effectively utilised, wherever practicable, in screening noise

from on- |

Noise control/ During construction |

Contractor(s) |

|

ü |

|

N/A |

|

|

|

site construction activities. |

|

|

|

|

|

||

|

S5.7 |

Use of Quite Powered Mechanical Equipment (QPME). |

Noise control/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

|

|

S5.7 |

Movable noise barriers of 3m in height with skid footing should be used and located within

a few metres of stationary plant and mobile plant

such that the line of sight |

Noise control/ During construction |

Contractor(s) |

|

ü |

|

N/A |

|

|

|

to the NSR is blocked by the barriers. The length of the |

|

|

|

|

|

||

|

|

barrier should be at least

five times greater than its height. |

|

|

|

|

|

||

|

|

The noise barrier material should have a superficial surface |

|

|

|

|

|

||

|

|

density of at least 7 kg m-2 and have

no o or gappeningss. |

|

|

|

|

|

||

|

S5.7 |

The noise insulating sheet should be deployed such that |

Noise control/ During |

Contractor(s) |

|

ü |

|

N/A |

|

|

there would be no opening or gaps on the joints. |

construction |

|

|

|||||

|

S5.7 |

Construction activities (e.g. excavation/shoring, reinstatement (asphalt), and pipe

jacking) will be

planned |

Noise control/ During construction |

Contractor(s) |

ü |

ü |

|

Implemented |

|

|

|

and carried out in sequence, such that items

of PME |

|

|

|

|

|

|

|

|

|

proposed for these activities will not be operated |

|

|

|

|

|

|

|

|

|

simultaneously. |

|

|

|

|

|

|

|

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S5.7 |

PMEs will

not be used

at the works

areas near educational institutions with residual impact (ie

the “influence area” within a

radius of 40m) during school hours in order to reduce impact to the educational institutions. |

Noise control

/ During construction |

Contractor(s) |

|

ü |

|

N/A |

|

|

S5.7 |

Noise enclosures or acoustic sheds

would be used

to cover stationary PME such as generators.

Portable/Movable noise enclosure

made of material with superficial surface density

of at least 7 kg m-2 may be used for screening the noise from operation of the saw/groover, concrete. |

Noise control/ Pre- construction/ During construction |

Contractor(s) |

ü |

ü |

|

N/A |

- |

|

S5.9 |

Sawcutting pavement,

breaking up of pavement, excavation /shoring, pipe laying, backfilling,

reinstatement (concrete) and pipe jacking

shall be scheduled outside the examination period. |

Noise control/ Pre- construction/ During construction |

Contractor(s) |

ü |

ü |

|

N/A |

-- |

|

S5.9 |

In view the duration of noise exceedance at Creative Secondary School, PLK Laws Foundation College, TKO Kei Tak Primary

School and School of Continuing and Professional

Studies-CUHK is limited to 8 weeks, the construction

work in the influence areas near the four schools

shall be scheduled during long school holidays (e.g., summer

holiday, Easter holiday

or Christmas holiday, etc.) as far as practicable. Scheduling the construction work for the four

schools. |

Noise control/ Pre- construction/ During construction |

Contractor(s) |

ü |

ü |

|

N/A |

- |

|

S5.10 |

A noise monitoring programme shall be implemented for the construction phase. |

Designated monitoring stations as defined in EM&A Manual/During construction phase |

ET |

|

ü |

|

N/A |

- |

|

S5.10 |

The effectiveness of on-site

control measures could

also be evaluated through the regular site

audits. |

All facilities/ During construction |

Contractor(s)/ ET & IEC |

|

ü |

|

Implemented |

- |

Note: D - Design stage C - Construction O - Operation

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

Water Quality |

||||||||

|

S6.9 |

Dredged marine sediment will be disposed of in a gazetted marine

disposal area in accordance with marine dumping permit conditions of

the Dumping at Sea Ordinance (DASO). |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

Dumping at Sea Ordinance (DASO) |

|

S6.9 |

Disposal vessels will be fitted with tight

bottom seals in order

to prevent leakage of material during transport. |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

Barges will be filled to a level,

which ensures that

material does not spill over during transport to the disposal site and that adequate freeboard is maintained to ensure that the decks are not washed by wave action. |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

After dredging, any excess

materials will be cleaned from decks

and exposed fittings before the vessel

is moved from

the dredging area. |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

All vessels should be well maintained and inspected before

use to limit any potential discharges to the marine environment. |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

All vessels must

have a clean

ballast system. |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

No discharge of sewage/grey wastewater should be allowed. Wastewater from potentially contaminated area on

working vessels should be minimized and collected. These

kinds of wastewater should be brought back to port and

discharged at appropriate collection

and treatment system. |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

No soil waste is allowed to be disposed overboard. |

Marine Dredging/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S6.9 |

Silt

removal facilities such as silt traps or sedimentation facilities will be provided to remove silt particles from runoff to meet the requirements of the TM standard under

the WPCO. The design of silt removal

facilities will be based on the guidelines provided in ProPECC PN 1/94. All drainage

facilities and erosion and sediment

control structures will be inspected on a regular basis and maintained to confirm proper

and efficient operation at all times

and particularly during

rainstorms. Deposited silt and grit

will be removed

regularly. |

Land site &

drainage/ During construction |

Contractor(s) |

|

ü |

|

Implemented reminder issued |

ProPECC PN 1/94 TM Standard under the WPCO |

|

S6.9 |

Earthworks to form the final surfaces will be followed up with surface protection and drainage

works to prevent erosion caused by

rainstorms. |

Land site & drainage/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

Appropriate surface

drainage will be designed and provided

where necessary. |

Land site &

drainage/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

The precautions

to be taken at any time of year when rainstorms are

likely together with

the actions to be taken

when a rainstorm is imminent or forecasted and actions to be

taken during or after rainstorms are summarized in Appendix A2 of ProPECC PN 1/94. |

Land site &

drainage/ During construction |

Contractor(s) |

ü |

ü |

|

Implemented |

ProPECC PN 1/94 |

|

S6.9 |

Oil interceptors will be provided in the drainage system where necessary and regularly emptied to

prevent the release of oil and

grease into the storm water drainage system

after accidental spillages. |

Land site &

drainage/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S6.9 |

Temporary and

permanent drainage pipes and culverts provided

to facilitate runoff discharge, if any, will be adequately designed for the controlled release of storm flows. |

Land site &

drainage/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 |

The temporary diverted drainage, if any, will

be reinstated to the original condition when the construction

work has finished or when the

temporary diversion is no longer required. |

Land site & drainage/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S6.9 |

Appropriate numbers of portable toilets shall be provided by a licensed contractor to serve

the construction workers

over the construction site to prevent direct disposal of sewage into the water environment. |

Land site &

drainage/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S6.9 and S6.12 |

The sterilization water

should be dechlorinated with total residual chlorine (TRC) level below 1

mg/L before discharge to public

sewer. In situ

testing of TRC should

also be conducted for the discharge of chlorinated water for pipeline disinfection to ensure

sufficient dichlorination before

discharge to public sewer. |

Sterilization of water mains prior to commissioning |

Contractor(s) |

|

ü |

ü |

N/A |

Technical Memorandum for Effluents Discharged into Drainage and Sewerage Systems |

|

S6.9 |

The cleaning and flushing water

should also be treated and desilted

to the relevant discharge requirement stipulated in TM-DSS before discharging. |

Sterilization of water mains prior to commissioning |

Contractor(s) |

|

ü |

ü |

Implemented, observation issued |

Technical Memorandum for Effluents Discharged into Drainage and |

|

S6.9 |

Site drainage

should be well maintained, and good construction

practices should be observed to ensure that

oil, fuels, solvents and other chemicals are

managed, stored

and handled properly and do not enter the nearby water streams. |

Land site &

drainage/ During construction/ During operation |

Contractor(s) |

|

ü |

ü |

Implemented, reminder issued |

- |

|

S6.12 |

Regular site inspections will be carried out in order to confirm that regulatory requirements are

being met and that contractors are

implementing the standard site practice

and mitigation measures as proposed to reduce potential impacts to water quality. |

During construction |

Contractor(s)/ ET & IEC |

|

ü |

|

Implemented, reminder issued |

- |

Note: D - Design

stage C - Construction O - Operation

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of

the recommended measures

& main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

Waste Management |

||||||||

|

S8.5 |

Nomination of

approved personnel to be responsible for standard

site practices, arrangements for collection and effective disposal to an appropriate facility of all wastes generated at the site. |

Contract mobilization/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S8.5 |

Training of site personnel in proper waste management and chemical handling procedures.

Training will be provided

to workers on the concepts of site cleanliness and appropriate waste management procedures, including waste reduction, reuse and recycling at the beginning of the construction works. |

Contract mobilization/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S8.5 |

Provision of sufficient waste

disposal points and regular collection for disposal. |

All area/ During construction/ During operation |

Contractor(s) |

|

ü |

ü |

Implemented, reminder issued |

DEVB TC(W)

No. 8/2010, Enhanced Specification for Site Cleanliness and Tidiness. |

|

S8.5 |

Appropriate measures to reduce windblown litter and dust transportation of waste by either covering trucks

or by transporting wastes in

enclosed containers. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

|

|

S8.5 |

A waste management plan (WMP) as stated in the “ETWB TC(W) No. 19/2005, Environmental

Management on Construction Sites” for

the amount of waste generated, recycled and disposed of (including the disposal sites)

will be established and implemented during the construction phase as part of the Environmental Management Plan (EMP).

The Contractor will be

required to prepare the EMP and submits it to the Architect/ Engineer under the Contract for approval prior to implementation. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

|

|

S8.5 |

Separation of chemical wastes for special handling and appropriate treatment at the Chemical

Waste Treatment Centre at Tsing Yi. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

Chapters 2 & 3 Code

of Practice on the

Packaging, Labelling &

Storage of Chemical Wastes published

under the Waste Disposal Ordinance (Cap 354), Section 35 |

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of

the recommended measures

& main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S8.5 |

Regular cleaning and maintenance programme for drainage

systems, sumps and oil interceptors. |

Land site/ During construction |

Contractor(s) |

|

ü |

|

Implemented, reminder issued |

Waste Disposal Ordinance (Cap 354) |

|

S8.5 |

A recording

system for the amount of wastes generated/

recycled and disposal sites. The trip-

ticket system will

be included as one of the contractual requirements and implemented by the contractor(s). |

Land site/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

DEVB TC(W)

No. 6/2010, Trip Ticket

System for Disposal of Construction & Demolition Materials |

|

S8.5 |

Prior to

disposal of construction waste, wood, steel and other metals will be separated to the extent practical, for re-use

and/or recycling to reduce the quantity of waste to be

disposed of to landfill. |

All areas/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

|

|

S8.5 |

Segregation and storage of different types of waste in different containers, skips or stockpiles to enhance reuse or recycling of material and their proper

disposal. |

Land site/ During construction/ During operation |

Contractor(s) |

|

ü |

|

Implemented, reminder issued |

WBTC 32/92, The Use

of Tropical Hard Wood on Construction Site |

|

S8.5 |

Use of reusable non-timber formwork to reduce

the amount of C&D

materials. |

All areas/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

|

|

S8.5 |

Encourage collection of aluminium cans and

waste paper by individual collectors during construction with separate labelled bins provided to segregate

these wastes from other general

refuse by the workforce. |

Land site/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

ETWB TCW

No. 33/2002, Management

of Construction and Demolition Material Including Rock |

|

S8.5 |

Any

unused chemicals and those with remaining functional capacity will be recycled as far as possible. |

Land site/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S8.5 |

Proper storage and site practices to reduce the potential for damage or contamination

of construction materials. |

All areas/ During construction |

Contractor(s) |

|

ü |

|

Implemented, reminder issued |

- |

|

S8.5 |

Plan and stock

construction materials carefully to reduce amount of waste generated and avoid

unnecessary generation of waste. |

All areas/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of

the recommended measures

& main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S8.5 |

A Sediment Quality Report (SQR) for sampling and chemical testing of the sediment will be

prepared and submitted to the EPD for approval. The approved

detailed sampling and chemical testing will be carried out prior to the commencement of the dredging activities to confirm the sediment disposal method. |

Marine works/ During construction |

Contractor(s) |

|

ü |

|

N/A |

ETWB TC(W)

No. 34/2002 and Dumping at Sea

Ordinance (DASO) |

|

S8.5 |

The management

of dredged/ excavated sediment management requirement from ETWB TC(W) No. 34/2002 will be incorporated in the

Specification of the Contract Documents. |

Marine works/ During construction |

WSD/ Contractor(s) |

|

ü |

|

Implemented |

|

|

S8.5 |

The contractor will open a billing account with EPD in accordance with the Waste

Disposal (Charges for Disposal of Construction Waste) Regulation for

the payment of disposal charges. |

Contract mobilisation/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

Cap 354N Waste Disposal (Charges for

Disposal of Construction Waste) Regulation |

|

S8.5 |

A trip-ticket system

will be established in accordance with

DEVB TC(W) No. 6/2010 to monitor the reuse of surplus excavated

materials off-site and disposal of construction waste and general refuse at transfer facilities/ landfills, and to control fly-tipping. |

Contract mobilisation/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

DEVB TC(W)

No. 6/2010, Trip Ticket System

for Disposal of Construction

& Demolition Materials |

|

S8.5 |

The project proponent will also conduct

regular inspection of the waste management measures implemented on site as described in the Waste Management Plan. |

All area/

During construction |

Contractor(s)/ ET/ IEC |

|

ü |

|

Implemented |

ETWB TC(W)

No. 19/2005, Environmental Management on Construction Sites |

|

S8.5 |

A recording system

(similar to summary table as shown

in Annex 5 and Annex 6 of

Appendix G of ETWB TC(W) No. 19/2005) for the amount

of waste generated, recycled and disposed of (including the disposal sites) will be established during the construction phase. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

Annex 5 and Annex

6 of Appendix G of ETWB

TC(W) No. 19/2005 |

|

S8.5 |

Inert C&D materials (public fill) will be

reused within the Project

as far as practicable. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of

the recommended measures

& main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S8.5 |

Storage areas for chemical waste shall be covered to prevent

rainfall entering (water

collected within the bund must be tested and disposed of as

chemical waste, if necessary). |

All area/ During construction/ During operation |

Contractor(s)/ WSD |

|

ü |

ü |

Implemented |

|

|

S8.5 |

Storage areas

for chemical waste

shall be arranged so that incompatible materials are appropriately separated. |

All area/ During construction/ During operation |

Contractor(s)/ WSD |

|

ü |

ü |

Implemented |

|

|

S8.5 |

General refuse will be stored in enclosed bins or compaction units separately from

construction and chemical wastes. |

All area/ During construction/ During operation |

Contractor(s)/ WSD |

|

ü |

ü |

Implemented, reminder and observation issued |

|

|

S8.5 |

Adequate number

of waste containers will be provided to avoid

over-spillage of waste. |

All area/ During construction/ During operation |

Contractor(s)/ WSD |

|

ü |

ü |

Implemented |

DEVB TC(W)

No. 8/2010 Enhanced Specification for Site Cleanliness and Tidiness. |

|

S8.5 |

A reputable waste collector will be employed by the Contractor to remove general refuse from

the site, separately from

construction and chemical wastes, on a daily

basis to minimise odour,

pest and litter impacts. |

All area/ During construction/ During operation |

Contractor(s)/ WSD |

|

ü |

ü |

Implemented, reminder issued |

- |

|

S8.5 |

Recycling bins will be provided at strategic locations within the Site to facilitate recovery of recyclable materials (including aluminium can,

wastepaper, glass bottles and plastic bottles) from the Site.

Materials recovered will be sold

for recycling. |

All area/ During construction/ During operation |

Contractor(s)/ WSD |

|

ü |

ü |

Implemented |

- |

|

S8.5 |

To avoid any

odour and litter impact, accurate number of portable

toilets will be provided for workers on-site. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S8.5 |

The burning of refuse on construction sites is prohibited by law. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

Air Pollution Control Ordinance (Cap 311) |

|

S8.7 |

To facilitate

monitoring and control over the contractors’ performance on waste management, a waste inspection and audit programme will be implemented throughout the construction phase. |

All facilities/ During construction |

ET/ IEC |

|

ü |

|

Implemented |

- |

Note: D - Design

stage C - Construction O - Operation

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

Ecology |

||||||||

|

S9.7 |

For slope mitigation works within the Clear Water Bay Country Park, to avoid tree felling and

damages to trees, the exact locations of the flexible barrier foundation plates, soil

nails and rock

dowels can be adjusted during

detailed design, and a

setback distance from existing

trees is recommended to be maintained as far as practical. A detailed specification describing the exact

locations of the flexible

barrier foundation plates, soil nails and rock dowels will be prepared to illustrate how the setback distance from existing trees

would be implemented for tree avoidance. |

Slope mitigation works area/ During detailed design/ During

construction |

Contractor(s) |

ü |

ü |

|

N/A |

- |

|

S9.7 |

Pruning of tree canopies along the alignment of the flexible barriers shall be limited to a minimum. |

Slope mitigation works area/ During construction |

Contractor(s) |

|

ü |

|

N/A |

|

|

S9.7 |

The alignment of flexible barriers shall be optimized to preserve all species of conservation interest and minimize the impact to the existing vegetation as far as practicable. All individuals of Marsdenia lachnostoma within the slope mitigation areas shall be retained in- situ,

by positioning the alignment of flexible

barrier at a minimum 1.5m in a radius away from these individuals. |

Slope mitigation works area/ During detailed

design/ During construction |

Contractor(s) |

ü |

ü |

|

N/A |

- |

|

S9.7 and 9.10 |

At the detailed design stage prior

to the commencement of the slope

mitigation works, a vegetation

survey shall be carried out at the

slope mitigation areas within the Clear Water Bay Country Park

to assess the condition and identify

the location of each individual of Marsdenia lachnostoma and other flora species of conservation

interest that may be directly

affected by the construction works. |

Slope mitigation works area/ During detailed

design/ During construction |

Contractor(s) |

ü |

|

|

Implemented |

- |

|

S9.7 |

Temporary fencing will be installed to fence off the concerned species either in groups of individually within

the works area

and in the close proximity to prevent from

being damaged and

disturbed during construction. A sign identifying the site shall be attached to the fence and flagging tape shall be attached to the individuals to visualize their locations. |

Slope mitigation works area/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

EIA Reference |

Recommended Environmental Protection

Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S9.7 and S9.10 |

A specification for fencing and demarcating individuals of Marsdenai lachnostoma (or

other flora species of conservation interest, if found)

adjacent to the proposed alignment of the flexible barriers will be prepared to protect the species. |

Slope mitigation works area/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S9.7 |

Induction

training shall also be provided to all site

personnel in order to brief them on this flora of conservation interest including the

locations and their importance. |

Slope mitigation works area/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S9.7 |

The resident site supervisory staff will closely monitor the conditions of concerned individuals during construction of flexible

barriers in the close proximity. |

Slope mitigation works area/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S9.7 |

Erect fences

along the boundary of the works

area before the commencement of works to prevent vehicle movements and encroachment of personnel onto adjacent areas. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S9.7 |

Regularly check the work site boundaries to ensure that they are not breached, and that damage

does not occur

to surrounding areas. |

All area/

During construction |

Contractor(s)/ Environmental Team (ET) |

|

ü |

|

Implemented. |

- |

|

S9.7 |

Avoid any damage and disturbance, particularly those caused by filling and illegal dumping, to the surrounding habitats through

proper management of waste disposal. |

All area/ During construction |

Contractor(s) |

|

ü |

|

Implemented |

- |

|

S9.7 |

Reinstate

temporarily affected areas, particularly the

habitats of plantation and shrubland-grassland immediately after completion of construction works, through on-site tree/shrub planting. The tree/shrub species will be chosen with reference to those in the surrounding area. |

All area/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

|

S9.7 |

Affected habitats within the Clear

Water Bay Country Bay shall be reinstated by hydro-seeding and planting of climbers and native shrub

seedlings where practical upon completion of

the slope mitigation works. |

All area/ During construction |

Contractor(s) |

|

ü |

|

N/A |

- |

Note: D - Design stage C - Construction O - Operation

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

Landscape

& Visual |

||||||||

|

S11.10 & 11.11 |

The construction area and area allowed for temporary structures, such as the contractor’s

office, will be minimized to a

practical minimum. (MM1) |

All area/ Detailed design/ During

construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

Implemented |

- |

|

S11.10 & 11.11 |

At the detailed design stage, the design team will seek to minimize the landscape footprint of the Project and above ground facilities, while satisfying all

other requirements. (MM2) |

All area/ Detailed design/ During

construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

Implemented |

- |

|

S11.10 & 11.11 |

Design principles will be adopted to take into account the surrounding area, particularly Clear

Water Bay Country Park behind and

the nearby waterfront, with due consideration

given to: - green

roofs where practical (i.e. without equipment on the roof); - roadside planting; - aesthetic treatment of all structures; - vertical greening; - screen planting along application site;

and - landscape

enhancement with amenity planting where practical

including planting along the edge (site boundary)

fence with native shrubs where feasible, to

reduce their visual impact and blend them into the surrounding landscape. (MM3) |

All area/ Detailed design/ During

construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

Implemented |

- |

|

S11.10 & 11.11 |

All trees within the Project Site or the potential slope mitigation works area will be carefully

protected during construction

according to DEVB TCW No. 10/2013 - Tree Preservation

(MM4) |

All area/ Detailed design/ During

construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

Implemented, reminder issued |

ETWB TCW No. 3/2006

- Tree Preservation. |

|

S11.10 & 11.11 |

No tree within

the Country Park will be felled. Trees

within the Site unavoidably

affected by the works will be transplanted where

necessary and practical. For trees that

need to be felled, compensatory planting will be provided to the satisfaction of relevant

Government departments. A compensatory tree planting proposal including locations of tree compensation will be submitted

to seek relevant government

department’s approval, in accordance with DEVB

TC(W) No. 10/2013. (MM5) |

All area/ Detailed design/ During

construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

Implemented |

DEVB TC(W)

No. 10/2013 |

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

S11.10 & 11.11 |

Any slope

mitigation works necessary to address natural terrain hazards, will be minimized to minimize any potential environmental impact to the

Country Park e.g. soil nailing and rock stabilization will aim to avoid existing trees e.g. should any restoration of vegetation be necessary, the best planting matrix with native

species will be established, with the aim of

resembling the existing vegetation. (MM6) |

All area/ Detailed design/ During construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

N/A |

|

|

S11.10 & 11.11 |

Dredging works for the installation of intake structures and outfall diffusers should be

minimized to avoid or reduce any

potential environmental impacts to as low as

reasonably practicable (ALARP). The intake and outfall structures (e.g. intake openings and diffuser heads)

will be prefabricated and transferred to site for installation. (MM7) |

All area/ Detailed design/ During

construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

Implemented |

|

|

S11.10 & 11.11 |

All night-time lighting will be reduced

to a practical minimum both

in terms of number of level and will be hooded and directional. (MM8) units and lux level

and will be hooded and directional. (MM8) |

All area/ Detailed design/ During

construction/ During operation |

WSD/ Contractor(s) |

ü |

ü |

ü |

Implemented |

- |

Note: D - Design

stage C - Construction O - Operation

|

EIA Reference |

Recommended Environmental

Protection Measures/ Mitigation Measures |

Objectives of the recommended measures & main concerns to address |

Implementation Agent |

Implementation Stage |

Implementation Status |

Relevant Legislation & Guidelines |

||

|

D |

C |

O |

||||||

|

Landfill Gas Hazard |

||||||||

|

S12.7 |

During all works, safety procedures should be implemented to minimise the risks of fires and explosions, asphyxiation of workers and toxicity effects resulting from contact with contaminated soil and

groundwater. |

All area/ Detailed design/ During

construction/ During operation |

Contractor(s) |

ü |

ü |

ü |

Implemented |

- |

|

S12.7 |

During trenching

and excavation as well as creation of confined

spaces at near to or below ground level, precautions